AML3D commences ASX trading, sells first AM machine

April 23, 2020

AML3D Limited, an Australian start-up established to commercialise an Additive Manufacturing technology branded WAM® (Wire Additive Manufacturing), has commenced trading on the Australian Securities Exchange (ASX) after successfully raising $9 million with strong institutional backing, including Perennial Value Management (5.3% shareholder).

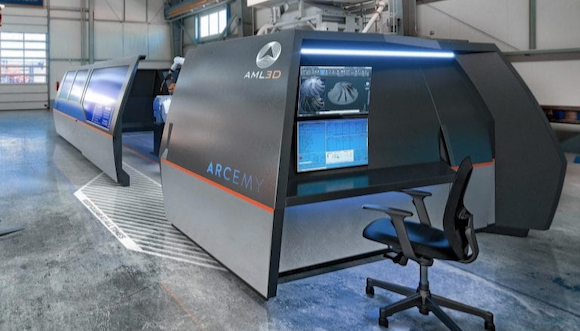

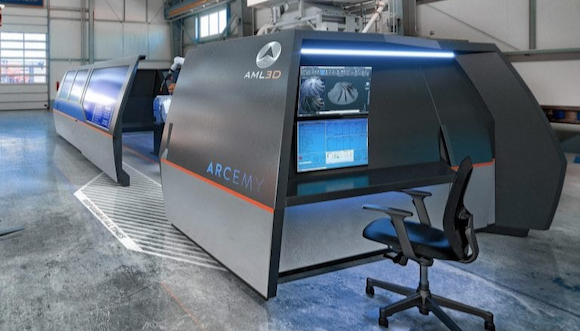

Funds from this Initial Public Offering (IPO) are expected to enable AML3D to continue its business expansion, establish an additional contract manufacturing centre to capture opportunities via contract manufacturing services, and build sales capacity of its Arcemy® AM machines.

Wire Additive Manufacturing

According to the company, WAM, a type of wire-based AM developed by AML3D, allows savings of up to 80% of material waste, making it more sustainable than casting and forging methods. AML3D states that its WAM process also provides the opportunity for design optimisation of parts, providing weight reductions of up to 30% without compromising in-service loads of up to 250 tonnes.

AML3D explains that it is currently preparing delivery of its first Arcemy metal AM machine to aerospace and defence prime, ST Engineering. The pricing is commercial in confidence and extends to AML3D the right to use 50% of the Arcemy’s up-time for contract manufacturing for other customers in the region.

ST Engineering is said to have paid a non-refundable deposit equal to approximately 15% of the contract value, with a further 30% payable on delivery of Arcemy for installation at ST Engineering’s premises. A final payment equal to the balance of the contract is payable on formal handover of ownership of the AM machine at the end of the rental period, subject to the machine meeting performance requirements and ST Engineering taking up the ownership option.

Successful marine application

AML3D delivered an additively manufactured Panama Chock for Keppel Corporation Limited in January 2020. Used in marine applications, the Panama Chock was reportedly a paid trial for the customer to ascertain performance via third party testing and future production volumes. The ability of the WAM process to competitively deliver certified, large, custom components for shipbuilding and repair at shorter lead times was said to have been of significant value to Keppel.

“We are excited about the potential of supporting our customers who are global leaders in the industries of marine and defence,” stated Andrew Sales, AML3D’s Managing Director. “These customers are a true testament to AML3D, highlighting the capacity of our innovative technologies and validating our experience and the team’s ability to implement deals with blue-chip global companies.”