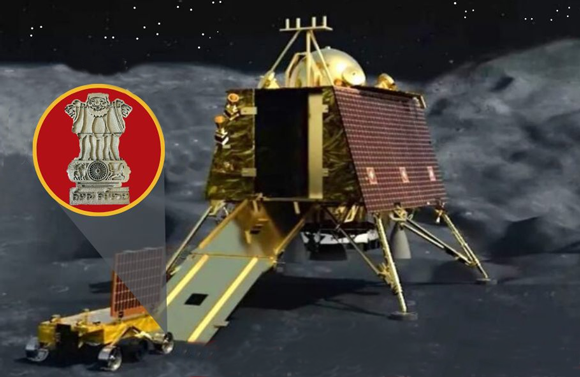

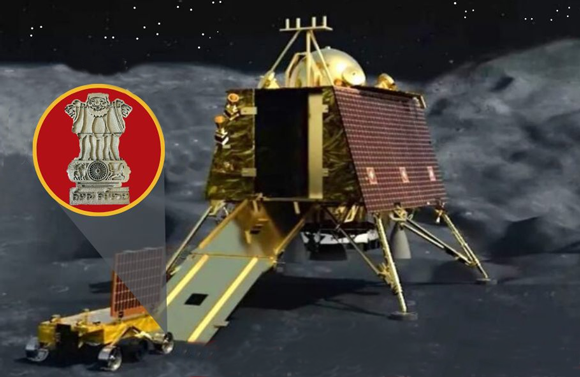

amace’s metal Additive Manufacturing stamps India’s national emblem on the moon

September 6, 2023

The Indian Space Research Organisation (ISRO) celebrated a number of milestones with the success of the Chandrayaan-3 moon-landing mission. Among the many contributors to this achievement was amace Solutions Pvt Ltd, an Additive Manufacturing solutions provider based in Bangalore, India.

As part of the project, amace Solutions additively manufactured the Indian National emblem, the Lion Capital of Ashoka at Sarnath, that adorns the wheels of the Pragyaan Rover. This imprints the emblem on the moon surface with each rotation of the wheel.

The team at amace Solutions worked to ensure that the emblem not only met the highest technological standards, but also embodied the essence of India’s cultural and historical heritage. The emblem was made from m4p™ AlSi10Mg aluminium powder suppled by m4p material solutions GmbH, a powder technology and service provider located in Austria and Germany.

As the rover embarks on its mission to explore the moon’s surface and gather valuable insights, the additively manufactured emblem is intended to serve as a visual reminder of India’s contributions to space exploration.

Download Metal AM magazine