AM 4 Industry project publishes cost-benefit tool to identify suitable AM components

March 31, 2020

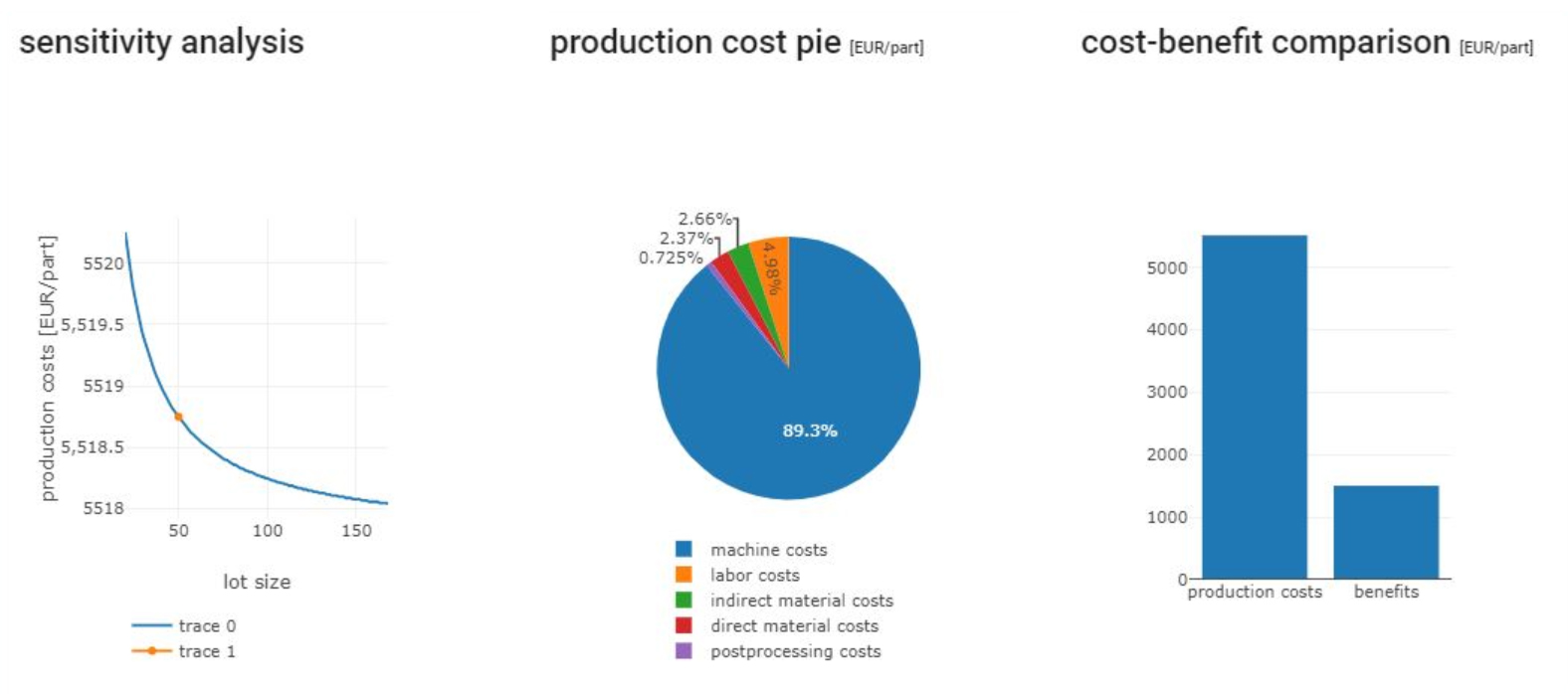

Researchers from RWTH Aachen University and have published a cost-benefit tool for AM as part of the ‘AM 4 Industry’ project (Courtesy ‘AM 4 Industry’)

The Ecoplus Plastics and Mechatronics Cluster, based in Lower Austria, has reported that researchers Tobias Schröer and Sören Münker from the Research Institute for Rationalization (FIR) at RWTH Aachen University and part of the of the Collective Research Network (CORNET) project ‘AM 4 Industry’ led by Ecoplus Plastics and Mechatronics Clusters, have developed a practical cost-benefit tool that helps companies identify components suitable for Additive Manufacturing.

The researchers explained that deciding on the use of Additive Manufacturing processes in a company can be very challenging, and is often based on incomplete information and time-consuming trial-and-error tests. Practice shows that competitive advantage is often created only through deep integration of AM into the value chain. For example, the cost advantages of lightweight components manufactured using AM are achieved through reduced fuel consumption over the part’s whole lifetime.

Thus, a classic comparison of manufacturing costs is often insufficient for obtaining a realistic assessment of the economic advantage. The researchers believe that what is needed is a holistic model that can compare not only the costs but also the technological advantages at a very early stage to help identify new benefits and accelerate decision-making processes. With this goal in mind, Schröer and Münker have developed an advanced cost-benefit tool as part of the ‘AM 4 Industry’ project.

The model reportedly helps to assess the individual cost-benefit ratio in a structured way by acknowledging specific product characteristics and already known advantages of the AM technologies. It takes into account the entire life cycle of product design/engineering, production/quality and service/after-sales in order to determine the most economically-promising applications out of the totality of the potential applications. As a result, the practicable model enables industrial users to compare different production methods for specific parts and supports well-founded and accelerated decision-making.

“Capturing the potential of Additive Manufacturing and exploiting it is a major practical challenge,” stated Tobias Schröer, Head of Production Management at the RWTH Aachen and co-developer of the cost-benefit model. “The cost-benefit tool clearly shows how to identify possible business cases by comparing costs and benefits at an early stage.”

The ‘AM 4 Industry’ project comprises eight renowned research partners and fifty-one companies from Austria, Germany, and Belgium, who have spent two years researching the successful industrial use of Additive Manufacturing processes. The primary goal of the project was to develop models to support companies in successfully integrating AM in production technologies. In contrast to existing approaches, the newly developed cost-benefit model allows the identification and evaluation of Additive Manufacturing not only in terms of costs but also of generated benefits.

The cost-benefit model can be downloaded via network’s website.