Alpha Laser to present closed-circuit AM machine at Formnext 2021

November 5, 2021

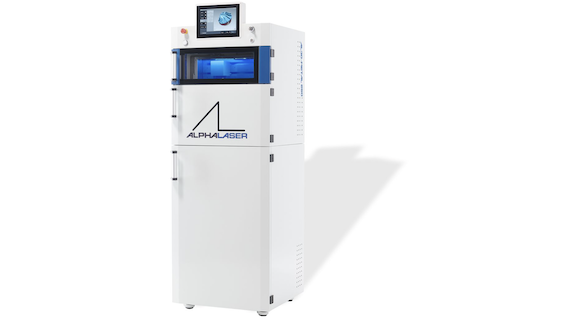

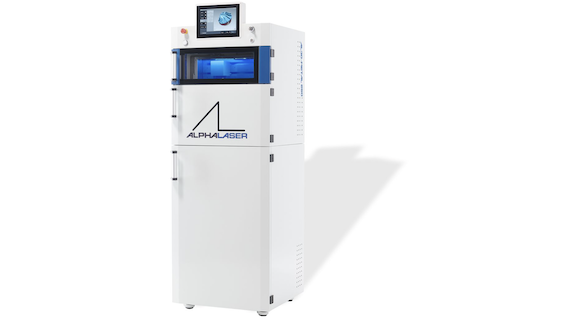

Alpha Laser GmbH, Munich, Germany, will present its AL3D-METAL 200 Laser Beam Powder Bed Fusion (PBF-LB) machine at Formnext 2021. The AL3D-METAL 200 features a closed powder circuit, wherein the introduction of the powder and removal of the additively manufactured component take place within a cartridge circuit. This method allows for greater operator safety, as they do not come into contact with the powder during the AM process.

The cartridge system is also said to reduce machine set-up time, as an operator is only required to select a cartridge filled with the required material and insert it into the AM machine before selecting the build file. The CAD build file is transferred to the AL3D-OS software, wherein parts can be arranged and support structures added. As parameters can be adjusted layer by layer, object by object, Alpha Laser has suggested that this is optimal for R&D.

Once the component is complete, the cartridge is inserted into the AL3D-CABIN unpacking station where the component is separated from the powder. Any excess powder is then collected or vacuumed directly in bottles for further processing or reuse. The integrated suction device with connection to external powder suction devices offers all common options for powder recycling.

In addition to the above, the cartridge also has integrated the wear parts, meaning the machine requires fewer maintenance cycles and, as a result, is said to have a long service life with replacements made simpler to install without the help of a technician.

Aside from the possibility of R&D, the AL3D-METAL 200 is said to be well suited to the jewellery, dental, medical, and tooling sectors due to its ability to produce fine, complex geometries. The machine is available with a build platform of either 50 mm or 100 mm in diameter.