Alloyed collaboration results in high-strength alloy for automotive sector

December 3, 2021

Grainger and Worrall, Bridgnorth, Shropshire, UK, has partnered with Alloyed, Oxford, UK, to develop a new aluminium alloy, ABD®GWA3, with improved strength, maintained ductility and good castability at production scale. The specifications for this application also aligned with a wider global push for lighter, more efficient propulsion systems.

Grainger and Worrall is a family-owned company that provides a range of manufacturing processes, including small-series, high-integrity structural castings. Since its beginnings in 1946, the company has aimed for continuous growth in its manufacturing processes to maintain and improve the quality of its castings as new technologies emerge. As part of this, the company sought to improve the performance of a complex cast-aluminium engine block.

The existing aluminium alloys used for this application – designated GW133® and GW116® –have been through extensive approvals and validation of the material. The aim was to improve on the specified properties of these alloys within the existing validation framework.

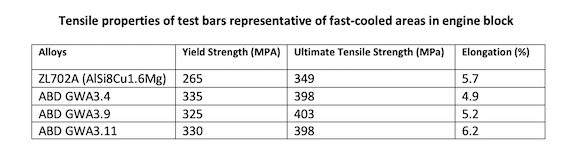

Using Alloyed’s ABD® platform – a simulation platform that provides optimisation and heat treatment options based on performance predictions – Grainger and Worrall identified three optimal alloy compositions in line with its targets. Designated ABD GWA3.4, ABD GWA3.9 and ABD GWA3.11, the ABD models for these compositions predicted that the strength and ductility would hit the target requirement for the engine block application.

Alongside developing the alloys, Alloyed also developed new heat treatment cycles utilising ABD’s simulation and empirical validation capabilities to further improve strength and ductility in the alloys whilst balancing additional manufacturing costs.

These new alloy compositions were then tested under full casting production conditions, under which the proprietary alloy, ABD GWA3, when coupled with a unique heat treatment, provided a 30% improvement in yield strength without sacrificing ductility. This was in line with predictions made by ABD.

Since development, these new compositions have been validated to operate successfully within the approved manufacturing tolerances and are said to greatly exceed the performance of the GW133 and GW116 alloys.