Air New Zealand investigating metal Additive Manufacturing for aircraft parts

August 9, 2018

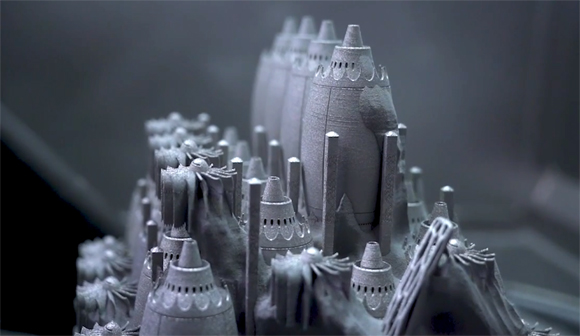

Metal additively manufactured wine aerators before post-processing, produced by Zenith Tecnica for Air New Zealand (Courtesy Air New Zealand)

Commercial airline Air New Zealand has partnered with Zenith Tecnica, Auckland, New Zealand, to investigate the production of metal additively manufactured for aircraft and tools. Zenith Tecnica specialises in the design and manufacture of parts from titanium and other metals using Electron Beam Additive Manufacturing (EBAM), using machines from Arcam EBM, a GE Additive company.

Bruce Parton, Air New Zealand’s Chief Operations Officer, explained that the airline is committed to innovation though Additive Manufacturing with new materials, stating: “It’s fantastic to be able to team up with and support local operator Zenith Tecnica and work with global company GE Additive to learn and collaborate in this space. While we are in the initial stages of working with these companies on 3D printing, so far, we have printed prototype metal framing for our Business Premier cabin, to quickly test new concepts and ideas and we have also made novelty wine aerators.”

Parton noted that while these novelty aerators – designed in the shape of aircraft engines – may look frivolous, they represent the genuine possibilities offered by metal AM for cost and space efficiency. “Aircraft interiors are made up of tens of thousands of parts, and the ability to 3D print on demand lightweight parts we only require a small number of, rather than rely on traditional manufacturing methods is of huge benefit to our business, without compromising safety, strength or durability,” he explained.

Martyn Newby, Managing Director, Zenith Tecnica, added, “This is a good project to demonstrate the strength, versatility and utility of titanium 3D printed parts for aircraft applications, and it’s very exciting to be working alongside Air New Zealand on this journey. We are in a very good position to support the local adoption of 3D printing for aviation applications and welcome Air New Zealand’s enthusiasm to embrace this emerging technology and help take it to the mainstream.”

Air New Zealand began investigating Additive Manufacturing in 2016 and has now moved on to the development of items such as improved small parts for IFE screens, as well as working with new partners such as ST Engineering Aerospace on more advanced parts. The airline stated that it is also exploring new processes with Auckland University, Victoria University of Wellington and other technology companies.