AIM3D successfully closes funding round to strengthen sales ahead of launching their new Additive Manufacturer

July 10, 2023

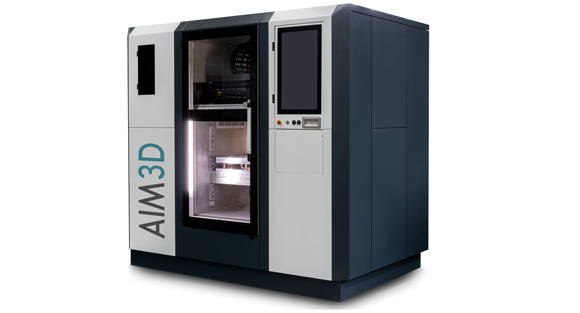

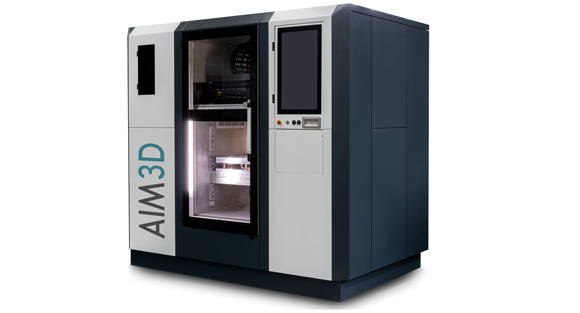

AIM3D GmbH, Rostock, Germany, has reported that it has successfully completed a funding round based around its existing investors. The HZG Group, High-Tech Gründerfonds (HTGF) and other early-stage investors are further supporting the startup ahead of the launch of the series production of its ExAM 510 industrial Additive Manufacturing machine.

AIM3D’s technology aims to make commercially available injection moulding granulate usable as a raw material for Additive Manufacturing. Instead of relying on filament, customers will reportedly be able to continue using the established and broadly available raw material as a granulate after switching technologies. In addition to the cost reduction from material savings, the use of the AIM3D machines comes with the freedom of Additive Manufacturing without the need for any moulds. If required, metal and ceramic components can also reportedly be produced using the company’s own Composite Extrusion Modelling (CEM) process, a form of Material Extrusion (MEX).

Clemens Lieberwirth, co-founder and CTO of AIM3D, shared, “With the ExAM 510, we are now on the home stretch. The feedback from our beta customers will be considered in the final series production later this year. With the support from our existing investors, we can, at the same time, take the sales pipeline to the next level and expand our own machine park to rapidly demonstrate our technological capabilities based on specific customer needs.”

Gregor Haidl, Senior Investment Manager at HTGF, added “We are pleased to further support AIM3D as a pioneer in the field of granulate 3D printing. The team’s innovation is impressive and it is fascinating to see how the boundaries between injection moulding and 3D printing continue to blur.”

Alongside the increased focus on sales, AIM3D, as a spin-off of the University of Rostock, looks to remain active in the field of research and development.

The team of engineers filed another basic patent last year; the voxelfill process allows material to be injected into volume chambers, filling the voxels and thereby creating a ‘brick bond’ in the component and offsetting the fracture line in order to increase productivity. A funded project is said to begin in the middle of the year, in which the team will develop and test the innovation on industrial applications.

In the future, AIM3D is looking to equip its existing Additive Manufacturing product portfolio with new intuitive operating software. Lieberwirth concluded, “Existing AIM3D customers will also benefit from a software relaunch, as the systems on the machines can be updated. The use of our machines should not require any firm prior knowledge of 3D printing and should therefore be open to all employees in our customers’ production.”

Download Metal AM magazine