AIM3D offers new, quicker multi-material extruder

August 23, 2021

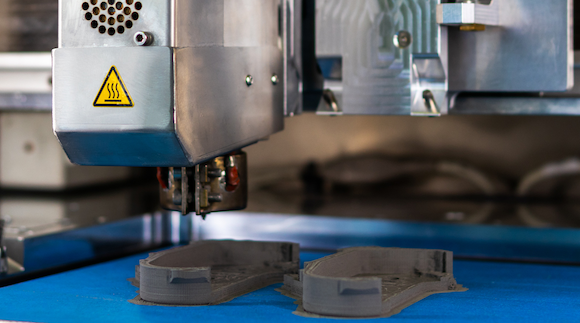

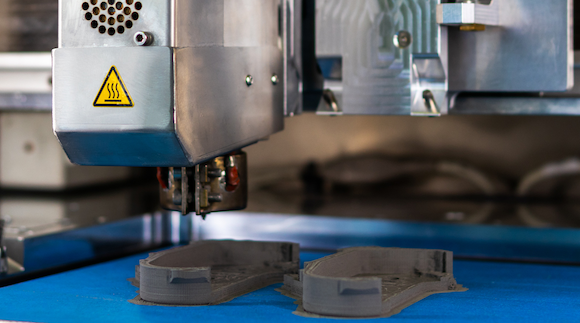

AIM3D GmbH, a spin-off company of the German University of Rostock who recently joined the MTC, has released a new generation of print heads for its Material Extrusion (MEX) process that it calls composite extrusion modelling (CEM). The new CEM-E2 extruder is a multi-material Additive Manufacturing print head that can produce metal (version ‘M’), ceramics (‘C’) and plastics (‘P’).

The new extruders are said to offer improvement in accuracy, enabling a higher surface quality and better mechanical properties in the component. Extrusion speed has been increased by more than 200%, with manufacturing rates of up to 220 cm³/h with a 0.4 mm nozzle now possible.

“The material feed as well as an optional water cooling system and an improved holder for the quick-change system are all new developments,” stated Clemens Lieberwirth, CTO. “The patented CEM-E2 extruder with its parameters tailored to specific materials sets new standards in the CEM processes.”

The appeal of CEM technology lies in the use of an AM machine for multiple materials. In addition, cost savings can be achieved by dispensing with filaments in favour of conventional pellets used. The most significant benefit, however, is said to be in the reduction in component build times through the direct use of pellets.

AIM3D is currently developing larger pellet AM machines in order to be able to manufacture larger parts and achieve even higher build rates. The launch of these products is planned for Formnext 2021 in Frankfurt, Germany.