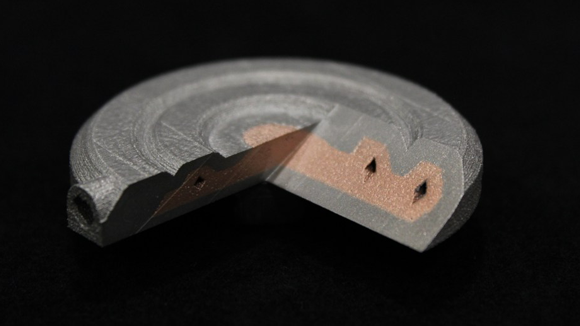

Aerosint additively manufactures its first dual metal part

March 14, 2020

Aerosint, Liège, Belgium, reports that it has additively manufactured its first dual metal part, produced on the Aconity Midi + machine. The machine was designed by the company’s partner Aconity 3D GmbH, Herzogenrath, Germany, to enable Aerosint’s multi-material powder deposition technology to be integrated.

According to Aerosint, this is a major breakthrough for Additive Manufacturing, as multi-metal AM gives designers and engineers the degree of freedom to make better parts; no other technology is thought to currently be capable of producing such dual-metal parts.

The integration of Aerosint’s dual-metal recoater in Aconity3D’s Midi + Laser Powder Bed Fusion (L-PBF) machine enabled the use of 316L and CuCrZr to build the test part. Consisting of 174 layers of 40 µm each, the part has a height of 6.9 mm and diameter of 55 mm. An integral 1.7 mm channel is featured within the CuCrZr portion. The part build time was said to be approximately 5.4 hours.