Aerojet Rocketdyne receives $1.79 billion NASA contract for additional moon mission engines

May 2, 2020

Aerojet Rocketdyne, Los Angeles, California, USA, has been awarded a $1.79 billion contract modification from NASA for the production of an additional 18 RS-25 engines to support future deep space exploration missions, in support of NASA’s Artemis Program to return America to the Moon.

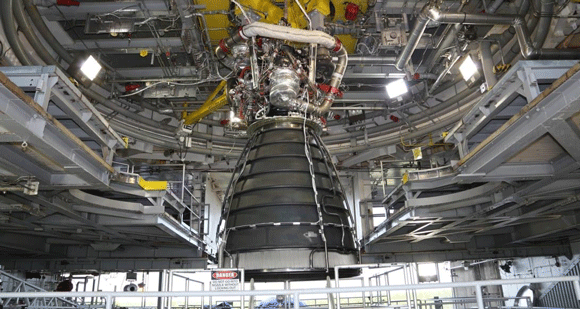

The flight proven, high-performance RS-25 engines are used to propel NASA’s Space Launch System (SLS) rocket, a critical element of the Artemis program. As NASA looks to land the first woman and next man on the Moon with the Artemis program, SLS is the super heavy-lift rocket that will carry the crew and cargo to the lunar vicinity.

There are currently sixteen RS-25 engines remaining from NASA’s Space Shuttle Program that have been upgraded, tested, and are ready to support the first four SLS missions. Aerojet Rocketdyne is already building six new expendable RS-25 engines that target more than a 30% cost reduction on future production when compared to the versions that flew on the Space Shuttle. Delivery of these new engines will begin in 2023.

The additional 18 engines continue to leverage supply chain optimisation and the incorporation of modern manufacturing techniques, like metal additive manufacturing, that were introduced in the initial SLS engine production.

The RS-25 engines used on the SLS are reported to contain multiple metal AM components. One is a vibration dampening device, the pogo accumulator assembly. The pogo accumulator assembly is a complex piece of hardware consisting of two components – the pogo accumulator and pogo-z baffle – and acts as a shock absorber to dampen oscillations caused by propellants as they flow between the vehicle and the engine. This is important component to ensuring a safe flight by stabilising these potential oscillations.

“The nation is returning to the Moon and moving forward with plans to explore other deep space destinations, including Mars,” commented Eileen Drake, Aerojet Rocketdyne’s CEO and president. “This contract ensures our flight proven RS-25 engines will be there every step of the way as NASA successfully and safely achieves these objectives.”

The first four RS-25 engines for the Artemis I SLS flight have reportedly been integrated with the core stage, which is undergoing green run testing at NASA’s Stennis Space Center. Later this year, all four engines will be fired simultaneously, as they will in flight, on the B-2 test stand.

The second set of four engines for Artemis II is said to be complete and is stored at Aerojet Rocketdyne’s facility at Stennis. Once the Artemis II core stage that is being built at NASA’s Michoud Assembly facility in New Orleans, Louisiana, USA, is complete, the engines will be ready for integration.