Admaflex 130 software updates released – including monitoring solutions

June 21, 2021

Admatec, Goirle, the Netherlands, has released software version 1.2.1.1 for its Admaflex 130, an Additive Manufacturing machine using a form of Vat Photopolymerisation (VPP) to process both ceramics and metals. The machine is an open system that comes standard with complete software, enabling full control of the AM process with an interface which allows the user to slice the part, add support structures as needed, apply offsets, customise and optimise parameters before and during the manufacturing process.

The new update now offers automatic support generation, video-based monitoring with an enhanced video player and remote process monitoring allowing the pause/resumption of a manufacturing job.

The new automatic support generation feature is said to be well suited for geometries that do not have a flat side, such as medical implants and jewellery. The automatic support generation software allows a user to create different types of support structures quickly and easily. The number of supports can be chosen by varying the support angle and, between the support and the model, a gap can be created, allowing easy removal of the part.

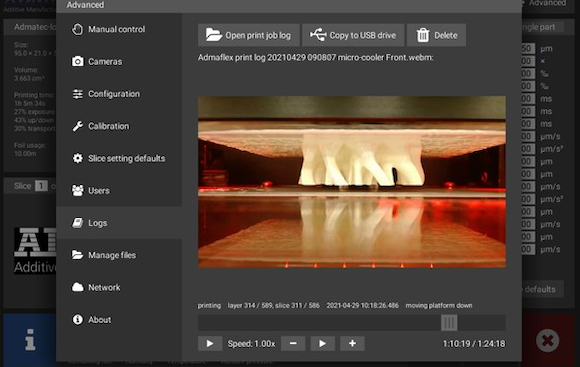

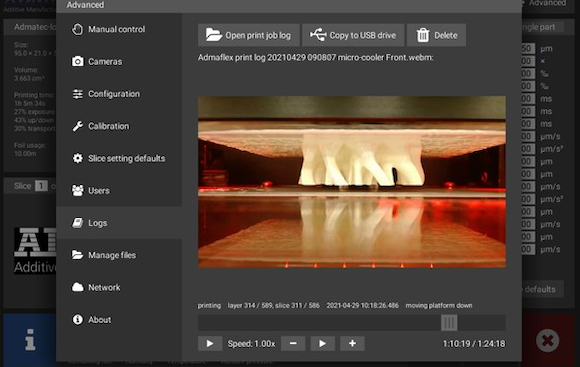

The video-based monitoring features enable the creation of time-lapse videos of the manufacturing job. A video player has also been added, allowing users to view any recording made by the machine directly on the machine. The video player supports scrubbing through the video, pausing the video at any point and changing the playback speed. The manufacturing action in the video is also displayed together with time and layer information.

When the Admaflex machine is connected via Ethernet to a network, via any laptop or desktop PC, users have remote access to the machine for easy exchange of build- or logfiles.

Remote connection capability also allows monitoring of the manufacturing job, including real-time video capture. New in the web interface is the option to pause the current job – this enables users to immediately react to what is happening on the machine from anywhere. If an issue is noticed and the user is not near the machine, the job can be paused, allowing the chance to get to the machine in order to fix the problem, and then continue the manufacture.