AddUp and Dassault Aviation aim to automate serial AM in aerospace sector

November 24, 2022

AddUp, headquartered in Cébazat, France, and Dassault Aviation are collaborating to bring automated metal Additive Manufacturing processes into the aerospace sector. With the aerospace industry facing challenges to maintain and increase its competitiveness, the use of metal Additive Manufacturing, under industrial-scale production conditions, is expected to offer a solution.

It is in this context that the collaborative R&D project Aeroprint, coordinated by Dassault Aviation, was set up, with the help of numerous partners, research centres, universities, and industries, of which AddUp is a part. Structured over five years, this project aims to develop, qualify and implement a competitive pre-industrial demonstrator of multi-material metal AM (Ti and Al), to manufacture complex aeronautical parts certified in classes 2 and 3. The Dassault Aviation site in Argonay in the Auvergne-Rhône-Alpes region of France has been identified as a pilot for the implementation of this process.

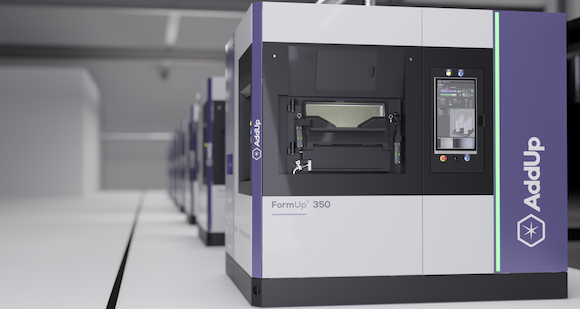

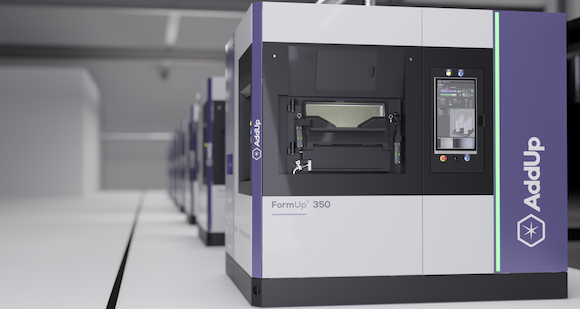

AddUp will be in charge of developing a new production system based on interoperability and robotisation of processes. The automated workshop will allow, thanks to AM, series production as well as multi material part production for aviation. The objective is to pool the equipment while ensuring the separation and proper circulation of the two materials chosen. AddUp’s team is working on a new type of closed enclosure that allows the powder to enter on one side and a tray of metal parts to exit on the other. This future workshop will be composed of two production units of four FormUp® 350 machines based on Laser Beam Powder Bed Fusion (PBF-LB) AM technology, as well as the necessary finishing needs.

After a phase of joint research and development to explore all the project’s requirements, AddUp is now working on the full-size model to verify and validate the principles retained, from mechanical design to autonomy. AddUp Manager, equipped with an ultra-fast trajectory generation engine, allows the preparation of production files by accessing more than 250 modifiable variables and customisable fusion strategies. Monitoring, a key issue for such a project, will be carried out using the already available AddUp Dashboards software and enhanced by bricks developed for this purpose.

AddUp Dashboards allows users to view production data in real-time, monitor the shop floor, and quickly analyse machine events. Among the pre-configured views offered in the software is a customisable map that shows real-time progress, remaining production time, and current status. Users can thus access data from a production run made a few months earlier and follow production in progress via the same tool.

Once complete, this precursor automated workshop will be the basis of a ready-to-use industrial solution for the deployment of Additive Manufacturing in existing production facilities.