Additively manufactured titanium hinge in Honor Magic V2 folding mobile phone

July 25, 2023

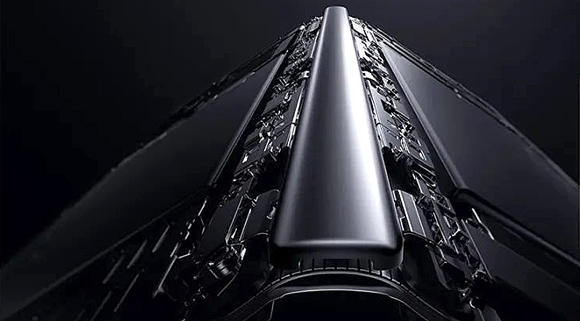

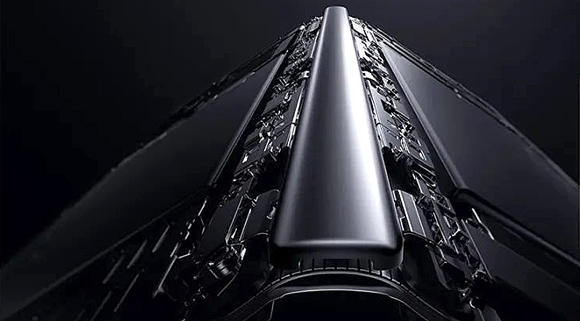

The recently launched Honor Magic V2 folding mobile phone includes a titanium hinge manufactured via Laser Beam Powder Bed Fusion (PBF-LB), making it the first high-volume 3C device to use Additive Manufacturing in the final production process. The phone is a new generation of mobile device that features a foldable screen, and at just 9.9 mm thick when closed and weighing 231g, is reported to be the thinnest and lightest foldable phone currently available from any manufacturer.

Being one of the key components in the phone, the hinge has been tested to operate for 400,000 folds – which equates to being opened and closed over one hundred times a day for ten years.

The hinge was developed by Honor, with the involvement of several Chinese Additive Manufacturing companies, including HBD and Eplus3D. The hinge shaft cover is made of titanium alloy, which makes the component lighter and thinner and is crucial to reducing the overall thickness and weight of the folding screen.

After the shaft cover has been additively manufactured, it is sent to a further supplier for grinding and polishing before being delivered to Honor. Eplus3D stated that the cost of the additively manufactured raw part was approximately $4, with the cost of grinding and polishing stage adding around $40. However, compared to a more traditional manufacturing method, this cost was said to be affordable and the process more efficient.

“Honor is very confident in this product and is currently placing an order. The volume has doubled from that of the previous generation, and the first batch of orders is about one million units,” added Eplus3D quoting an unnamed supplier in the mobile phone supply chain.

Celine Xie, Overseas Business Development & Marketing Manager at HBD told Metal AM magazine that the significance of this achievement extends beyond the Honor Magic V2. “Reports have surfaced indicating that the next generation Apple Watch Ultra will also incorporate titanium 3D printing, partially replacing traditional CNC milling technology.”

Although the use of metal Additive Manufacturing in the Apple watch is as yet unconfirmed, it would represent a major breakthrough for the technology. “This transition highlights the industry’s recognition of the immense potential offered by 3D metal printing in terms of enhanced product design and functionality. The growing trend of integrating 3D metal printing in various 3C products emphasises its increasing importance in the consumer electronics industry,” added Xie.

Download Metal AM magazine