Additive Manufacturing transforms RF antenna design

June 21, 2017

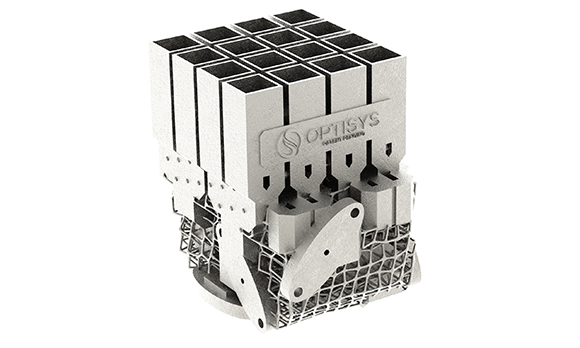

The palm-sized, lightweight, one-piece, AM antenna component

Optisys LLC, Grapevine, Texas, USA, is a provider of sophisticated, metal additively manufactured micro-antenna products for high performance aerospace and defence applications. The company has recently completed a project that documents the significant advantages of employing metal Additive Manufacturing to produce such systems.

Antennas are critical for conveying information, such as voice, video and data, across long distances. They are widely employed in commercial and military aircraft, spacecraft, satellite communications, unmanned aerial vehicles and by ground terminals and land-based troops. Yet the complex radio frequency (RF) components that make up an antenna system can be large and heavy, characteristics that can impact mobility and performance.

“Companies in the commercial and military space are pressured for shorter lead-times, lighter weight and smaller antennas,” explained Clinton Cathey, Optisys CEO. “By combining RF design simulation, mechanical engineering, and system optimisation focused on AM, we provide metal 3D-printed antenna products at greatly reduced size, weight, lead-times, part count and cost – with as-good or better RF performance than conventionally manufactured systems. We’re creating structures that were simply not possible to produce in the past.”

The test-piece demonstrator project involved a complete redesign of a high-bandwidth, directional tracking antenna array for aircraft, known as a Ka-band 4×4 Monopulse Array. Optisys performed every aspect of the design work in-house and printed the component in a single piece on their Concept Laser machine.

“Concept Laser’s powder-bed fusion in particular is perfect for this application because of the fine resolution it provides for antennas functioning in the one to one-hundred Gigahertz range of RF in which most of our potential customers operate,” stated Cathey.

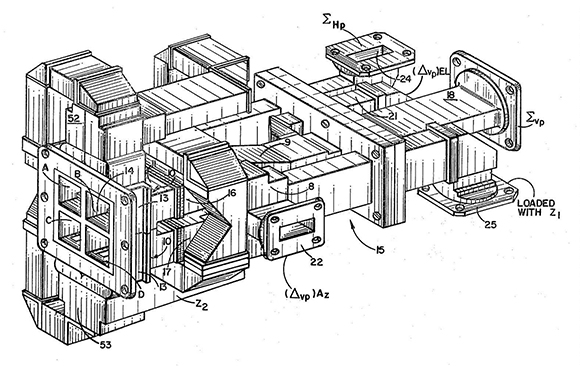

Manufacturing antenna systems via conventional methods such as brazing and plunge EDM is a complex, multistage process that can take an average of eight months of development time and three to six more of build time, stated Optisys COO Robert Smith.

“Our unique offering is that we redesign everything from an Additive Manufacturing perspective. We take into account the entire system functionality, combine many parts into one, and reduce both development and manufacturing lead times to just a few weeks. The result is radically improved size and weight at lower costs,” Smith explained.

Optisys conducted a profitability analysis on how their redesigned microwave antennae test piece compared to a legacy design that is conventionally manufactured. By optimising its design for Additive Manufacturing, Optisys achieved the following benefits:

- Part count reduction from a hundred discrete pieces to a one piece integrated assembly

- Weight savings of over 95%

- Lead time reduced from eleven months to two months

- Production costs reduced by 20-25%

- Non-recurring costs reduced by 75%

The plan for the original multi-part antenna assembly

Other advantages of Additive Manufacturing

“In addition to what our test-piece project revealed, 3D printing offers a number of other advantages,” stated Smith. “When we design multiple antenna components into a single part, we reduce the overall insertion loss of the combined parts. And because our antennas are so much smaller this also lowers insertion loss dramatically despite the higher surface roughness of AM build, for similar or even better RF performance than conventional assemblies.”

Optisys can manufacture in a variety of metals with its Concept Laser machine, though for antenna products aluminium is preferred because of its surface conductivity, light weight, corrosion resistance and strength under shock and vibration. “3D-printed metal will have virtually the same properties as a solid piece of the same material for RF performance. Structurally the products have been tested in rigorous vibration environments and they also have the same coefficient of thermal expansion (CTE) as wrought metals. This also gives them better stability over temperature than plastic RF components,” explained Smith.

Part consolidation through AM provides a number of downstream benefits as well. “Reducing part count also reduces assembly and rework. It’s easy to add features to an existing AM design, easier to assemble the finished components and, long-term, you have less testing, maintenance and service when you have fewer parts,” Smith concluded.