Additive Manufacturing of Bulk Metallic Glass using advanced laser beam shaping technology

March 25, 2024

Researchers at the Swiss Advanced Manufacturing Center, Bienne, Switzerland and Montanuniversität Leoben, Austria, have developed advanced laser beam shaping technology that has been used to additively manufacture Bulk Metallic Glass (BMG). In a study published in Advanced Functional Materials, Sepide Hadibeik, Hossein Ghasemi-Tabasi, and co-workers fabricated nearly fully amorphous, dense BMG samples using a shaped laser beam and established optimised atomic-scale short-and medium-range ordering, along with improved yield and fracture compressive strength.

The research article, ‘Controlling the Glassy State toward Structural and Mechanical Enhancement: Additive Manufacturing of Bulk Metallic Glass Using Advanced Laser Beam Shaping Technology,’ states that BMGs offer exceptional physical and mechanical properties, making them highly desirable for a variety of applications. Laser Beam Powder Bed Fusion (PBF-LB) has great promise for producing large and intricate BMG structures.

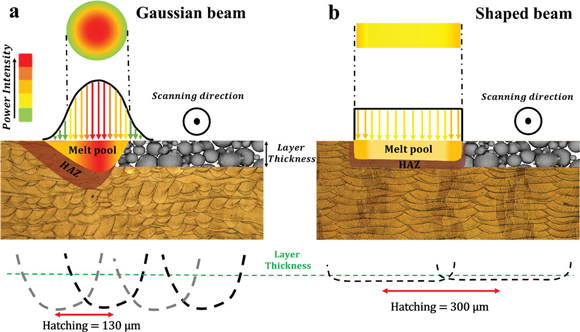

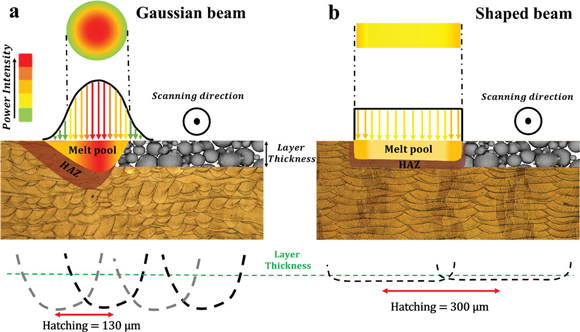

However, it was noted that using non-optimal energy distribution in current Additive Manufacturing machines leads to extensive reheating of previously solidified layers and, as a result, the mechanical characteristics can be significantly impacted by structural relaxation and partial crystallisation. In this study, a tunable advanced laser beam shaping technology was employed to overcome these difficulties.

The researchers explained that the formation of a shallow and wide melting pool geometry, using the beam shaping, allows for an increase in hatching distances to better control the thermal history, introducing improved amorphicity and rejuvenation. This higher rejuvenation and disordering allow for increased atomic mobility, which facilitates the creation and spread of shear bands, thus enhancing the mechanical strength and ductility of the material.

The current work demonstrates that BMG parts can be fabricated using flexible beam-shaping technology, allowing them to go beyond the capabilities of standard Additive Manufacturing techniques. However, it was also stated that the mechanical behaviour still deviates from that of the original as-cast state, necessitating further research into the amalgamation of structural and defect engineering methodologies for comprehensive understanding.

It was also highlighted that the freeform beam shaping technology has further potential to alter how PBF-LB processes will be developed. As freeform beam shaping is a fully digitally controlled technology, it can be integrated seamlessly with machine learning concepts since it eliminates the need for human interaction with the optics after initial installation. Furthermore, because the optical system is flexible and tunable, developing processes for new materials or application-specific optimisation will potentially become much faster. This could result in working processes for high-performance materials that were previously un-processable using PBF-LB, it was claimed.

The open access research article, published by Wiley, is available to read here.