Additive Industries and SMS group team up for industrial Additive Manufacturing serial production

November 14, 2017

Handshake after signing of the cooperation. From right to left: Guido Kleinschmidt (Member of the Managing Board of SMS group); Norbert Gober (Vice President Research and Development, SMS group); Daan A.J. Kersten (CEO, Additive Industries); Markus Hüllen (Vice President 3D Competence Center, SMS group) and Bernhard Steenken (Corporate Development, SMS group)

Additive Industries, The Netherlands and SMS group, Germany, have announced the joining of forces to develop and market a production system that will enable manufacturing companies break through into industrial scale serial production of metal AM components.

The two companies will bring together their specialist knowledge of the manufacture of metal powders and Additive Manufacturing systems. The production concept will not just encompass powder manufacturing and 3D printing, but include other stages right up to delivery of the finished component.

“The entire process is designed for maximum productivity, with the result that Additive Manufacturing can finally enjoy competitive success in serial production,” stated Guido Kleinschmidt, Member of the Managing Board of SMS group.

“As one of the world’s leading machine and plant builders for the metallurgical industry, we have extensive design know-how and process engineering expertise in the field of vacuum melting plants. We are now transferring this expertise to powder production plants,” added Norbert Gober, Vice President Research and Development at SMS group.

The process starting point is the manufacture of powder. To ensure maximum purity, the alloys are induction-melted under vacuum in the crucible. The liquid metal is atomised using pure argon in an oxygen-free atmosphere. “The quality of the powder manufactured is crucial for the quality of the finished product. To enable us to make faster progress in powder production, we are building an industrial-scale pilot system, which is scheduled to go live at the end of the year,” stated Markus Hüllen, Vice President 3D Competence Center at SMS group.

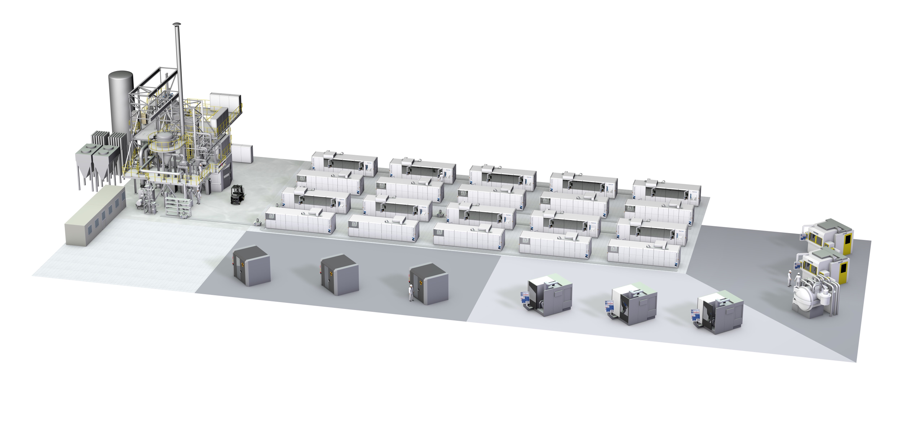

Plant concept of SMS group and Additive Industries for industrial additivemanufacturing serial production

The powder manufacturing process is followed directly by Additive Manufacturing. In the integrated MetalFAB1 system, the metal powder bed fusion process is applied to melt the powder in a reproducible and efficient way. After additively manufacturing the parts, the build plate with parts is automatically transported to the heat treatment furnace for a stress relief cycle before storage by a robot. The MetalFAB1 system is designed to run autonomously 24/7 without the need for multiple shifts, substantially reducing cost.

SMS group is also responsible for the heat treatment of the printed components for setting of improved material characteristics. Within the group, SMS Elotherm is the company with the induction heat treatment expertise, and one of the markets it supplies these machines to is the automotive industry. After the components have been machined and undergone quality control checks, they are ready to be shipped.

“Five years ago, we started with the development of the world’s first 3D metal printer for high-end production applications. Today, with our MetalFAB1, we are accelerating industrial additive manufacturing as one of the industry’s leading technology suppliers. In SMS group we have found a partner who has experience in planning production complexes such as these and delivering them on a turnkey basis,” added Daan A.J. Kersten, CEO of Additive Industries.

The first visible sign of this collaboration will be the Democenter, which is to be set up at SMS’s facility in Mönchengladbach in the next few months. Additive Industries will supply a MetalFAB1 printer, on which the powder produced by the plant is processed, and this will be installed right next to the pilot unit to work fully integrated.

“This Democenter will allow us to align the powder plant with its process guidance system perfectly with the printer and its parameters. We will then be able to apply this practical experience on an industrial scale and offer this as a turnkey solution to high-end users,” added Gober.