Lightweight accelerator pedal design for race car developed by Siemens

December 15, 2021

In a recent case study to demonstrate the benefits of using metal Additive Manufacturing in automotive applications, Siemens Digital Industrial Solutions used its Generative Design module in the Solid Edge platform to design an optimised accelerator pedal for a race car. The resulting design highlighted the improved performance, reduced environmental impact and material savings obtainable with metal AM.

In the original pedal design the part was assembled from four components, all of which were produced via a sheet metal manufacturing process. Utilising a Dual-Laser EP-M260 Laser Beam Powder Bed Fusion (PBF-LB) AM machine from Eplus3D, headquartered in Hangzhou, China, the new accelerator pedal was built as a single piece, reducing labour and inventory costs. A change from steel to AlSi10Mg also resulted in a 62% weight reduction.

To achieve the design in Solid Edge, a number of constraints are first set in the Generative Design module. In this step, the outer forces, pressures and torques that the part needs to withstand during usage are defined. After this, all surfaces that are fixed in certain directions or angles are set. After defining all constraints, a goal for the minimum safety (strength) factor or the desired weight is set, and the Generative Design process begins.

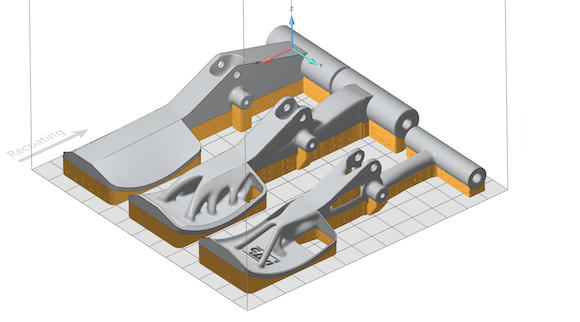

The case study produced three different models which were then optimised by Solid Edge sales partner ISAP as examples of generative design. One model shows the initial stage of an AM part; this weighs almost the same as the initial sheet metal part. The second version shows a part that has still a high safety factor and is partially optimised for topology. It weighs 373 g, a reduction in weight of around 14%. The third version is fully optimised and weighs only 164 g, a reduction in weight of 62%, yet is still a durable solution for the racing car accelerator pedal.

The generative design process using Solid Edge is available to view as a recorded webinar from Siemens.