3D Metalforge receives accreditation from Lloyd’s Register

August 20, 2018

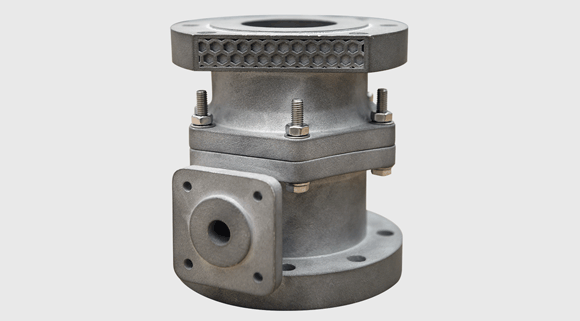

A marine gasket valve produced by 3D Metalforge using metal Additive Manufacturing (Courtesy 3D Metalforge Pte Ltd)

Metal additive manufacturer 3D Metalforge Pte Ltd, Singapore, has been accredited for excellent operational and quality assurance by Lloyd’s Register, an international provider of classification, compliance and consultancy services to the marine, offshore and other high value industries. The certification was conferred following a successful audit of 3D Metalforge’s facility capability, personnel, procedures, systems and equipment in July 2018.

The scope of the audit reportedly reviewed multiple areas of the business, such as the implementation of a Quality Management System (QMS), supplier control, process management, manpower training procedures, HSE (health, safety and environment) and the reception, handling and storage of material within 3D Metalforge’s Additive Manufacturing Centre. A critical portion of the audit also involved the certification of the entire metal Additive Manufacturing build process, as well as post-processing techniques that cater specially to the maritime sector.

3D Metalforge stated that it believes this certification will offer existing and potential customers in the marine, shipping and offshore industries assurance on the quality, safety and performance aspects of the final end-use products produced in its metal Additive Manufacturing facilities. Prior to receiving this accreditation from Lloyd’s Register, 3D Metalforge received a similar industry certification and successfully implemented the ISO9001:2015 quality framework certified by DNV GL in 2017.

These endorsements are expected to help steer 3D Metalforge’s growth as a sector-leading AM service provider focused on continual improvement, customer satisfaction and overall sustainable business performance. Matthew Waterhouse, 3D Metalforge CEO, who also serves as Chairman of the AM Technical Standards Committee set up by Enterprise Singapore, stated, “As a leading additive manufacturer in the maritime sector, we are very pleased to receive this endorsement from Lloyd’s Register to bring even more value to our marine and offshore customers and partners.”

“At this juncture, large format 3D printing in the maritime industry is developing rapidly,” he continued. “Quality and standards can therefore really help by providing a sustainable and practical framework for all partners in the ecosystem to advance AM procedures and technologies in a more structured manner.”