Erofio Group produces first AM part in trial of GE Additive’s Concept Laser M Line

June 4, 2021

Industrial moulding company Erofio Group, Batalha, Portugal, has successfully additively manufactured its first part using GE Additive’s Concept Laser M Line, having been chosen to test the machine ahead of its wider commercial launch planned for later this year.

The company’s AM leader Luis Santos and his team opted for a parameter previously used on the Concept Laser M2 Series 5, making only minimal changes to adapt it for the new M Line system. Following remote optimisation support from the GE Additive team in Lichtenfels, the part was successfully manufactured on its first attempt, over a six-day period in May 2021.

“We fully expected the first part to be printed on the M Line to go well,” stated Jan Siebert, General Manager, laser technologies, GE Additive. “And when it did there was a rush of excitement felt across the entire team here in Lichtenfels. Work continues here in Germany on the M Line, ahead of the launch, and we will factor in additional feedback from the team at Erofio.”

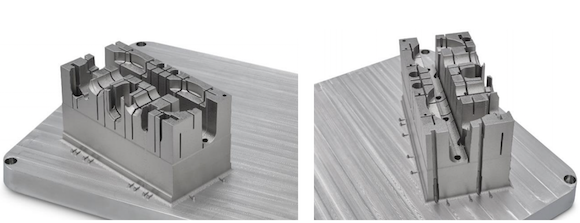

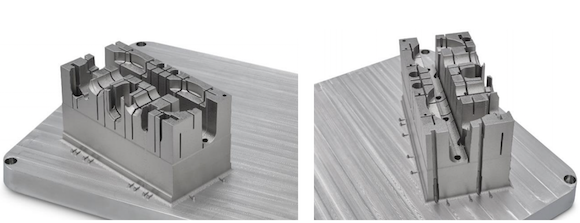

The AM part, a mould core, was manufactured using M300 hot work tool steel, often used for the production of injection moulding and die-casting tool inserts with conformal cooling, as well as functional components. The core contains more than eight independent, internal conformal cooling channels, stretching over 8 m in length and between 5 mm to 8 mm in diameter. The ability to manufacture this part using AM has enabled a more efficient heat exchange, which, in turn, increases process productivity as well as the productivity of the initial production; the company stated that the time to manufacture the core was reduced by 30%. This method of manufacture has also reduced the company’s finishing requirements by 90%.

“We are honoured to be part of GE Additive’s thorough commercial readiness process,” stated Santos. “We’re learning a lot from them and I think it’s safe to say they are learning a lot from us and our first impressions working with the M Line. Having the first part come off our system is a great milestone and we’re looking forward to supporting the wider team as the solution comes to market and beyond.”

“We have a solid working relationship with the team at Erofio that goes back well over a decade. As we near a critical phase in commercialising the M LINE system, we specifically sought out a trusted partner to gain early installation experience, data and honest customer feedback,” added Wolfgang Lauer, Concept Laser M Line Product Manager, GE Additive.

Siebert concluded, “It is critically important that when GE Additive brings new solutions to market, it can tangibly and immediately demonstrate business impact. Our M Line system operates at higher levels of reliability and repeatability, meeting customers’ needs from day one. This is not a science experiment and we are not developing laboratory equipment. Overly ambitious claims and incomplete specifications in other vendors’ product launch announcements only serve to undermine the trust that our wider industry has collectively built in metal additive technology in recent years.”