XJet to present world’s first direct 3D metal ink-jet system using nanoparticle jetting technology at formnext

November 9, 2016

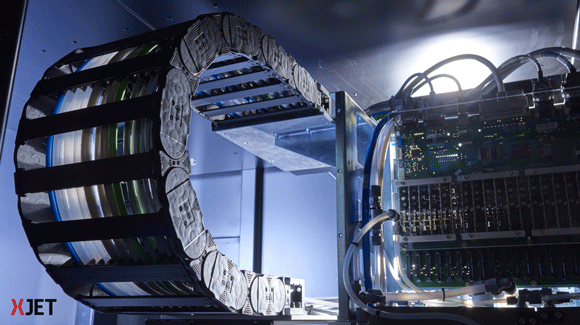

Internal view of the XJet system

XJet Ltd., Rehovot, Israel, has announced it will showcase the world’s first Additive Manufacturing system to directly jet metal ink at formnext 2016, Frankfurt, Germany, November 15 – 18, 2016. The inkjet technology uses nanoparticles which, it is claimed, produces high quality parts featuring unprecedented levels of detail, surface finish and accuracy, without compromising build time.

The company’s NanoParticle JettingTM process produces an ultra-thin layer of droplets containing metal nanoparticles or support nanoparticles. These are deposited onto the system build-tray, producing metal parts with the ease and versatility of inkjet printing without compromising throughput.

Delivered as sealed cartridges, the liquid dispersions are loaded into the XJet system, eliminating the need to handle metal powders. Inside the system’s build envelope, extremely high temperatures cause the liquid ‘jacket’ around the metal nanoparticles to evaporate. This results in virtually the same metallurgy as traditionally-made metal parts. In addition, the metal part undergoes a sintering process, with the support material removed simply and with almost no manual intervention.

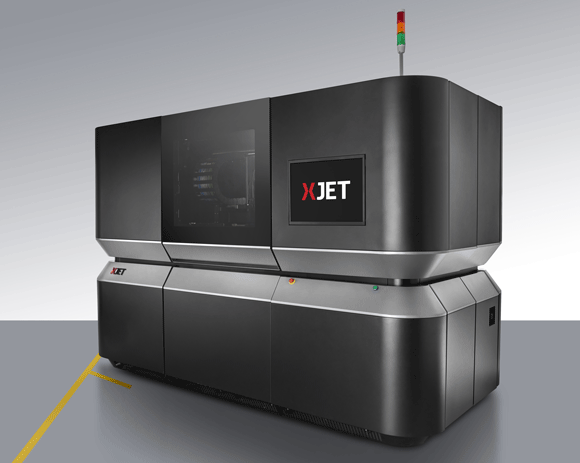

XJet’s AM system uses sealed cartridges, eliminating the need to handle metal powders

“We are currently witnessing how Additive Manufacturing is disrupting entire business models,” stated Yair Shamir, XJET’s Chairman, Managing Partner of the Catalyst CEL Fund and former Minister of the Israeli government. “Even more so with XJet’s NanoParticle Jetting technology, the manufacturing industry is going to make giant leaps ahead, giving businesses a real competitive edge. Its breakthrough technology produces complex geometries with intricate details, and with perfect metallurgy. This is unprecedented. It is exciting to be part of the XJet journey and to usher in this revolutionary approach in Additive Manufacturing.”

Prior to a successful introduction to the US market in RAPID earlier this year, XJet announced an additional funding round of $25 million. This was led by the Catalyst CEL Fund, an Israeli-Chinese private equity fund and Autodesk, Inc. through its Spark Investment Fund.

“We look forward to presenting our metal ink-jet system at formnext – the leading international event for Additive Manufacturing technologies,” stated Hanan Gothait, CEO and Founder of XJet. “We are extremely proud of our NanoParticle Jetting technology, which is a landmark in the Additive Manufacturing industry. It is the culmination of years of research in our labs, with over 50 registered patents. Our technology overcomes many of the current challenges that Additive Manufacturing has faced until now, which will greatly benefit many industries.”