Westinghouse celebrates 1,000th additively manufactured fuel flow plate for nuclear reactors

March 21, 2024

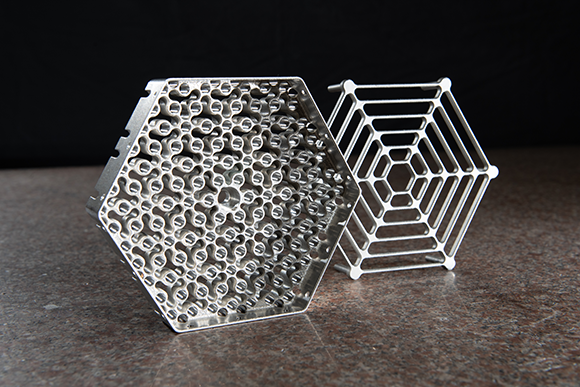

Westinghouse Electric Company LLC, a nuclear energy technology provider headquartered in Cranberry Township, Pennsylvania, USA, recently manufactured its 1,000th fuel flow plate using Additive Manufacturing. The fuel flow plate is reported to the first-ever safety-related AM component to enter serial production for the nuclear industry.

The additively manufactured flow plates are installed in VVER-440 fuel assemblies, enabling a redesign of the assemblies’ bottom part which is said to result in a more robust performance.

“This achievement showcases the development of Additive Manufacturing from prototyping to full-scale production, generating tangible value for our customers,” stated Lou Martínez Sancho, Westinghouse Chief Technology Officer and Executive Vice President, R&D and Innovation. “This marks another Westinghouse pioneering achievement in AM Technology holding the commitment to strengthen safety, efficiency, sustainability and energy security.”

In 2015, Westinghouse conducted a material irradiation study of AM nuclear components and in 2020, the company installed a safety-related additively manufactured component — a thimble plugging device — into an operating commercial reactor.

Westinghouse supplied the world’s first commercial pressurised water reactor in 1957 and the company’s technology is the basis for nearly half of the world’s operating nuclear plants.

Download Metal AM magazine