UPM and Ohio State’s CDME mark over two years collaboration in Additive Manufacturing

April 4, 2024

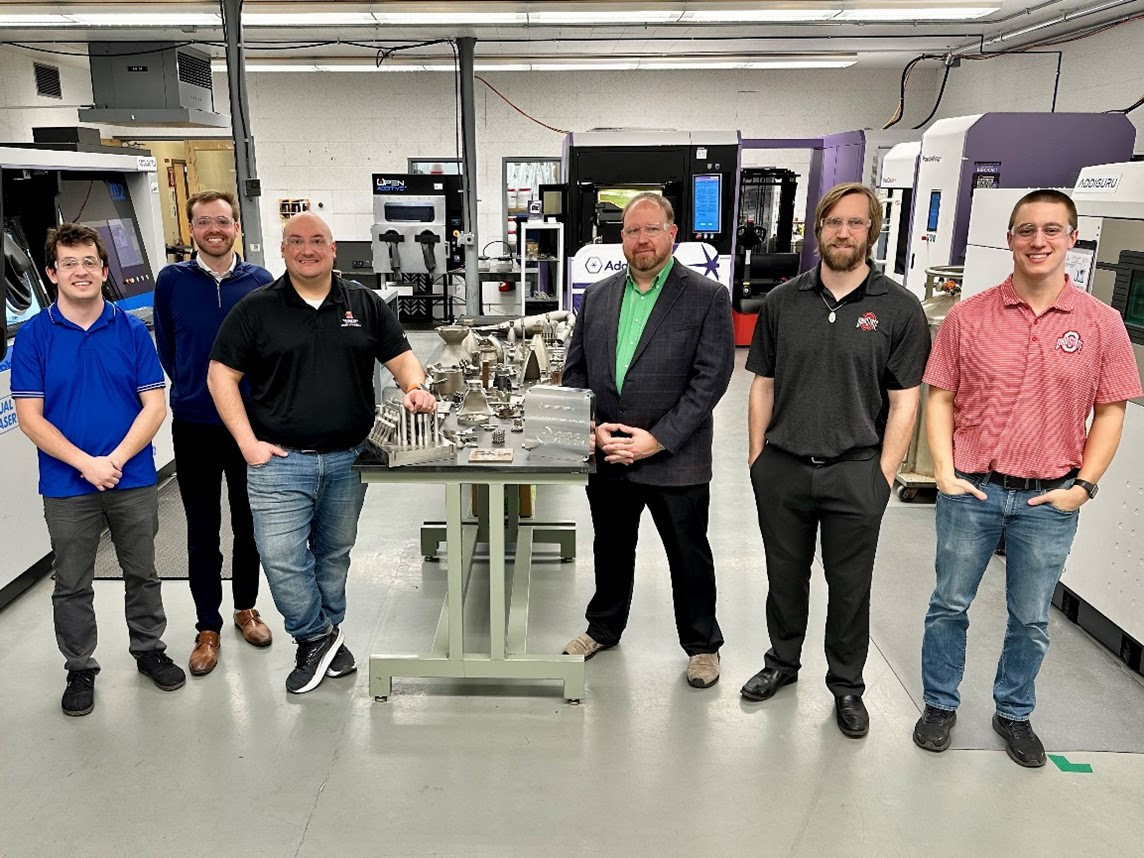

United Performance Metals Additive Solutions (UPM), headquartered in Cincinnati, Ohio, USA, has reported that it recently visited Ohio State’s Center for Design and Manufacturing Excellence (CDME), to mark over two years of collaboration and present the group with a commemorative build plate that will be displayed in its laboratory.

The collaboration started with UPM requesting a novel manufactured plate bottle opener. This project utilised the creativity of the CDME undergraduate students to develop a unique lattice structure to complement the simplistic design of metal additively manufactured build plates. Since then, the collaboration has grown to where UPM has hired CDME students, CDME is working with UPM on a regular basis for its EDM and grinding services and collaborating on a variety of projects within the CDME Additive Manufacturing lab.

Build plates are integral to AM processes like Powder Bed Fusion (PBF) and Directed Energy Deposition (DED). By presenting the commemorative plate, UPM acknowledges Ohio State’s pivotal role as a catalyst for progress and celebrates the collaborative spirit within its academic community.

Chris Prue, Application Development Manager for UPM Additive Solutions, stated, “Collaborating with CDME provides a glimpse into the next generation of additive designs and technology. UPM Additive Solutions is proud to support the continued efforts to accelerate development for projects by collaborating our services along with allowing students to understand the value chain.”

“We work with many small and large businesses similar to UPM,” shared Ben DiMarco, Additive Manufacturing Technology Leader at CDME. “A diverse ecosystem of collaborators allow our students a unique opportunity to learn and ultimately find a landing spot after they graduate.” This is said to be paramount to CDME’s mission to employ undergraduates in its research centre to supplement the undergraduate learning environment. “In recent projects we have worked with UPM to finish machine our plates, provide part services, and allow for improved logistics in complex manufacturing projects.”

Download Metal AM magazine