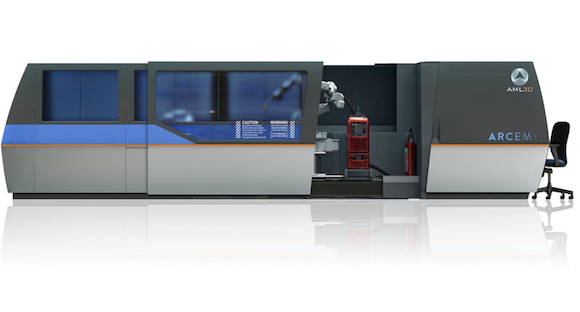

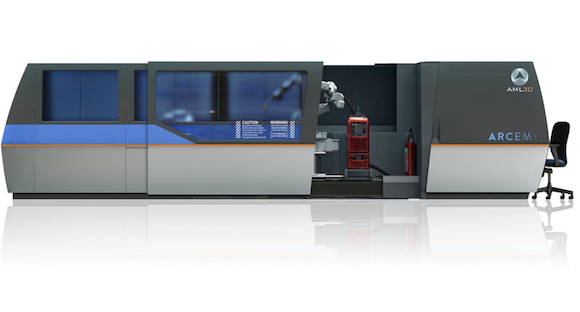

University of Queensland purchases AML3D Arcemy machine

October 22, 2021

AML3D Limited, Edinburgh, Australia, has sold an Arcemy® machine to the University of Queensland (UQ) for approximately AUS $400,000. Arcemy units are certified across a wide range of welding wire feedstock-based metals, which is said to make them more flexible than powder-based Additive Manufacturing machines. The machine uses a process the company calls WAM®, also known as Wire Arc Additive Manufacturing (WAAM), a wire-based form of Directed Energy Deposition (DED).

“We are thrilled to be able to supply UQ with what we believe is the world’s most sophisticated integrated wire-based 3D printing unit,” stated Andy Sales, Managing Director, AML3D. “There is an expectation that we will work closely with UQ in the future around specific R&D programs that will benefit both parties in research, industry application and students’ base learning and research.”

AML3D will work with the university in the installation and commissioning of this unit, which is expected to be used for education and research & development at UQ.