UKAEA and University of Birmingham agreement focuses on nuclear fusion

February 15, 2023

The UK Atomic Energy Authority (UKAEA) and the University of Birmingham have signed a framework agreement which will support the design, development and modelling of new fusion materials, and the Additive Manufacturing of materials capable of withstanding ultra-high temperatures. As part of the agreement, UKAEA will sponsor a Chair in Fusion Materials at the University.

“The University of Birmingham’s School of Metallurgy and Materials has a strong track record in the development of novel materials for extreme environments particularly through the design of novel compositions and microstructures,” stated Dr Amanda Quadling, Director of Materials Research at UKAEA. “We’re pleased to have this opportunity to use the University’s neutron source and to work with their excellent team of scientists.”

The agreement is said to mark an advancement in fusion energy development in academia and a shift from theoretical disciplines to real-world powerplant applications. This new Chair and partnership are expected to help to answer complex questions concerning the future of fusion energy production, such as the testing and evaluation of materials towards component qualification and plant availability metrics.

Finance invested in fusion energy enables new materials and technologies to be developed that can benefit not just fusion energy, but also a wide range of industries including space, healthcare and decommissioning. It is expected this partnership will attract collaborations from a wider range of industrial partners who will be able to sponsor students and work in partnership with them on research projects.

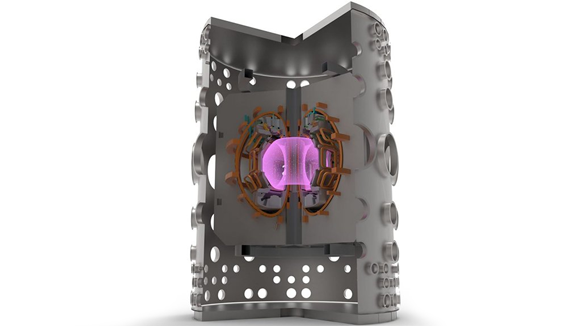

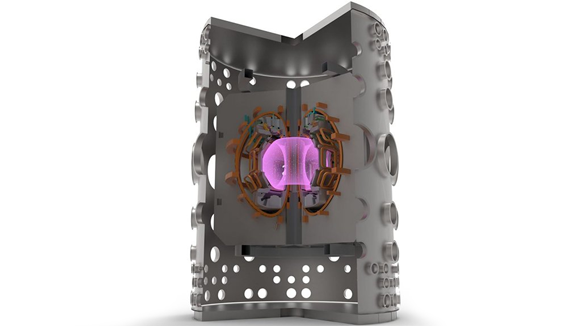

The agreement between UKAEA and the University follows last year’s announcement that West Burton A in Nottinghamshire was selected as the home of the Spherical Tokamak for Energy Production (STEP) prototype fusion powerplant, which will be delivered by UK Industrial Fusion Solutions Ltd (UKIFS).

The STEP prototype powerplant is due to complete construction by 2040 and aims to provide electricity to the grid from fusion energy. In order to make fusion commercially viable, new materials will need to be designed, developed and modelled. These materials will need to withstand the highly energetic neutrons released by the fusion reactions.

The partnership also follows University of Birmingham’s recent commission of its High Flux Accelerator-Driven Neutron facility. Added to the existing MC40 Cyclotron facility, this installation makes University of Birmingham an ideal place at which to study damage sustained by materials in fusion machines.

“The unique facilities and expertise at the University of Birmingham will enable us to make a significant contribution to the development of Fusion into a reliable and sustainable energy source,” added Professor Alessandro Mottura, Head of Materials at the University of Birmingham. “This agreement will build on years of fruitful collaboration between the University of Birmingham and UKAEA, and will contribute to strengthening the United Kingdom’s leadership in this sector.”

Download Metal AM magazine