Uddeholms AB to produce metal powders for Additive Manufacturing

April 3, 2017

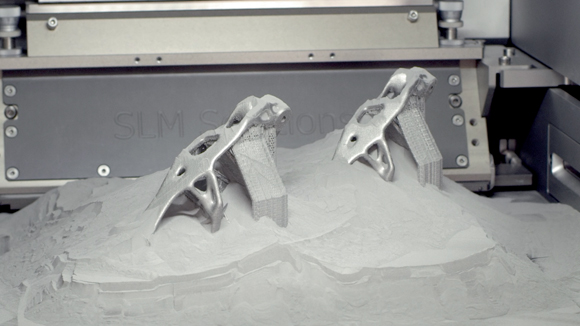

Part production at voestalpine’s Additive Manufacturing Centre, Düsseldorf, Germany (Courtesy voestalpine)

Uddeholms AB, part of the Special Steel Division of voestalpine Group, has announced the commencement of fine metal powder production at its new pilot plant at Hagfors, Sweden. The new plant is the result of ongoing investment at the site, which has seen voestalpine invest over €100 million in expanding technology and capacity at Uddeholms AB over the past decade.

Powders produced at Uddeholms’ Hagfors facility will be tested and processed into complex components at voestalpine’s Additive Manufacturing Centre, Düsseldorf, Germany, as well as being sold to external customers in the AM industry. According to the company, this will open up a new business segment for Uddeholms AB, and support voestalpine’s planned expansion into metal Additive Manufacturing in Asia and the NAFTA regions as a materials supplier.

“In order to reinforce the company’s global leadership in special steels for industrial tool manufacture, over the coming years further investments totalling around €30 million are planned, for new high-tech heat treatment facilities, as well as research establishments to further refine our steel grades. A focus of our future activities in Hagfors also lies in producing metal powders designed for use in 3D metal printers,” stated Franz Rotter, Member of the Management Board of voestalpine AG and head of the Group’s Special Steel Division.

voestalpine, which operates globally, has around 500 group companies and locations in more than 50 countries on five continents. In the business year 2015/16, the group generated revenue of €11.1 billion, with an operating result (EBITDA) of €1.6 billion. The group employs 48,500 staff worldwide.