U.S. Army Research Lab to license nanogalvanic aluminium powder for hydrogen generation

August 13, 2018

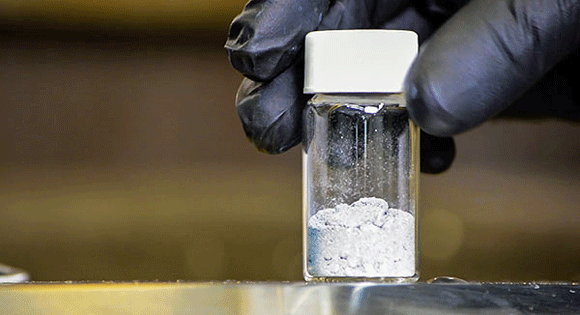

The laboratory stated that the powder has many advantages as a potential energy source (Courtesy U.S. Army Research Laboratory)

The U.S. Army Research Laboratory, Adelphi, Maryland, USA, has reported plans to license its discovery of a nanogalvanic aluminium powder for hydrogen generation. When combined with water or any water-based liquid, the novel, structurally-stable, aluminium-based nanogalvanic alloy powder reacts to produce on-demand hydrogen for power generation without a catalyst. Scientists on the project have speculated that, among other applications, it could potentially be used in metal Additive Manufacturing to create self-cannibalising robots/drones.

Dr Anit Giri, a scientist with the lab’s Weapons and Materials Research Directorate, explained the process by which the powder generates hydrogen: “This powder-based alloy includes material that disrupts the formation of an encapsulating aluminium oxide layer, allowing for the continuous production of hydrogen that can be used at the point of need to power a wide range of devices via fuel cells and internal combustion.”

Researchers from the lab’s Lightweight and Specialty Metals Branch discovered the unique properties of the nanopowder while investigating aluminum alloy compositions for other purposes. The laboratory has posted a Federal Register Notice and is inviting companies to submit their ideas on how best to commercialise this technology. The laboratory will then select the most appropriate partners and collaborators, after which license exclusivity will be determined.

The laboratory stated that the powder has many advantages, as a potential energy source which is stable as an alloy powder, is non-toxic, and is environmentally friendly. Because it can be transported in powder or tablet form and combined with any available water source, the discovery has the potential to eliminate reliance on high-pressure hydrogen cylinders.

It is also said to be extremely efficient as an energy source, with 1 kg of the powder generating 4.4 kWh of energy – enough to power ten 60 W incandescent light bulbs for more than seven hours, or the equivalent number of LED bulbs for over fifty hours.

“The researchers have demonstrated rapid hydrogen generation rates using powder and tablet forms of the alloy,” stated Branch Chief Robert Dowding. “The hydrogen has been shown to be useful for powering fuel cells and is expected to power internal combustion engines.”

Dr Giri added that the powder can be produced using current manufacturing techniques, from either pure or alloyed aluminium. “The manufacturing process is easily scalable and it is also very fast,” he stated, “with a 75% theoretical hydrogen yield in one minute at standard temperature and pressure, and 100% theoretical yield in three minutes.”

According to Dowding, the researchers are currently characterising the hydrogen generation rates and purity of the gas generated, as well as examining the effects of compositional changes to the alloy and systematic changes in the microstructure of the powders. In order to support a better understanding of the material, the laboratory has established a website to showcase the technology and review the process that will culminate in the granting of one or more patent licenses around September 2018.