Trumpf to showcase latest TruPrint generation at Formnext 2021

October 13, 2021

Trumpf Inc, Ditzingen, Germany, will showcase the latest generation of its TruPrint 3000 medium-format Laser Beam Powder Fusion (PBF-LB) Additive Manufacturing machine at Formnext 2021, Frankfurt, Germany, November 16–19, 2021.

The TruPrint 3000 is capable of additively manufacturing parts up to 400 mm in height and 300 mm in diameter. Designed to meet the quality and production-line requirements of various industries, the machine is reputedly capable of processing all weldable materials, including steel, titanium and aluminium.

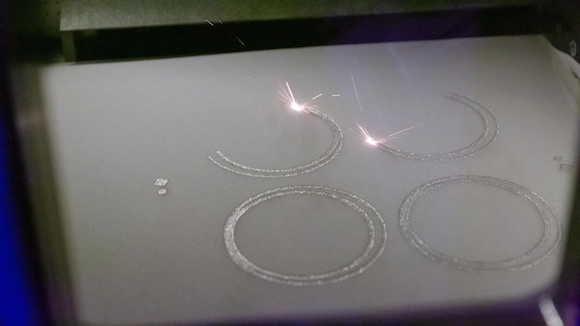

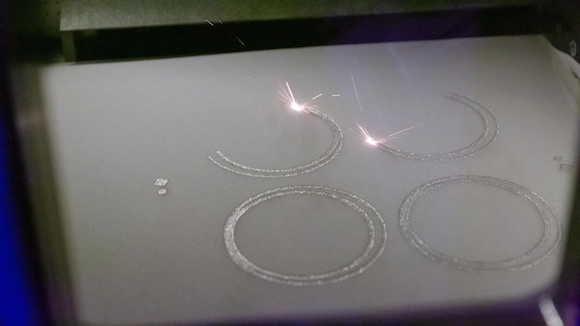

Another development in the new generation of machine is the ability to equip the TruPrint 3000 with a second laser, which enables the near doubling of its productivity while reducing costs. With the second laser equipped, two 500-watt lasers work in parallel across the machine’s entire build chamber, increasing manufacturing efficiency regardless of the geometry and number of fabricated parts.

Where required, each complete contour of the largest parts can be scanned by a single laser, thus eliminating seams in an effort to guarantee optimum part quality. The Automatic Multilaser Alignment option automatically monitors the lasers during the build stage to ensure they are aligned with one other at all times.

Trumpf’s team has also improved the movement of inert gas through the TruPrint 3000, allowing it to flow from back to front in a steadier and more uniform manner. As well as reportedly boosting the quality of manufactured parts, this allows the operator to remove excess powder from the part while it is still inside the machine, using an integrated powder conveyor. The excess powder is deposited in a powder container and can be reused for the next build job.

Further, the design of the machine and peripheral components allows the powder to be prepared in a shielded environment using an inert gas where required, thereby protecting the powder from external influences as it moves through the processing cycle, enabling consistent powder quality. This can be leveraged in industries such as medical device manufacturing.

The new generation of TruPrint 3000 also comes with built-in melt pool monitoring: high-speed sensors in the machine optics automatically monitor the melt pool during manufacture and record the optical fingerprint of each process. The machine includes intelligent analysis software which can be trained with a reference build job; the software will then present a graphical display of any deviations, such as a melt pool that is too cold or too hot. This gives operators the information they need to detect, rectify and analyse errors.