Titomic partners with Ascent Aerospace to produce metal tooling by AM

March 12, 2020

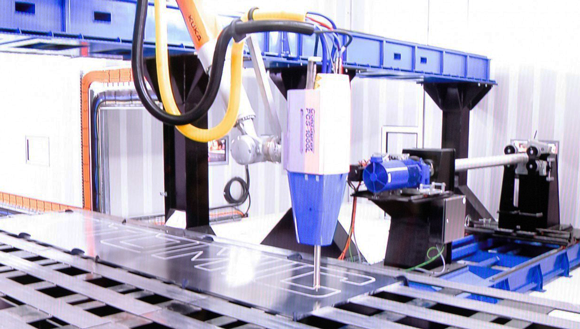

Titomic Limited, Melbourne, Australia, has signed a partnership agreement with Ascent Aerospace, Macomb Township, Michigan, USA, which will see the Titomic Kinetic FusionTM (TKF) process used to produce metal tooling for Ascent’s customer base. Ascent provides aerospace tooling systems, assembly automation and factory integration for the aerospace, defence and space industries.

The partnership will reportedly build on the current development activities of Titomic in order to produce metal tooling with reduced porosity andimproved tool wear resistance, and deliver a more sustainable green production process by reducing material waste. The partnership will consist of two phases:

Phase 1 – Validation phase

Titomic will deliver an Ascent customer-approved Invar36 tool, produced using the TKF9000 metal Additive Manufacturing system, and perform a test and production feasibility trial.

Phase 2 – Adoption phase

The partners will establish a joint sales strategy for the supply of aerospace tooling using TKF’s metal Additive Manufacturing process, in order to reduce the current lengthy lead-times required to meet growing global demand.

“The significant increase in the global tooling market is being driven by the aerospace and defence industries’ compounding need for higher production rates of carbon fibre parts,” stated Jeff Lang, Titomic Managing Director.

“The increased use of carbon fibre parts in commercial aircraft has created a backlog in the supply of tooling that is not being resolved,” he explained. “Titomic’s partnership with Ascent Aerospace makes strategic sense to further validate the commercial opportunities for industrial-scale metal Additive Manufacturing using Titomic’s TKF systems to resolve this current, and ongoing, backlog for tooling.”

Michael Mahfet, CEO of Ascent Aerospace, added, “Our focused research & development activities in Additive Manufacturing technologies aligns with Ascent’s multi-year technology roadmap and realisation of expansive efforts studying the benefits of these technologies within the aerospace tooling market.”

“Staying at the forefront of Additive Manufacturing positions us to remain the leader in new and innovative tooling solutions, supporting strong collaboration with our customers and supplementing our in-house, vertically integrated design and fabrication capabilities,” he continued. “We look forward to working with Titomic in the advancement of metallic 3D printing for the aerospace tooling industry.”