Swansea University brings small-batch metal powder production in-house with ATO Lab+

February 14, 2024

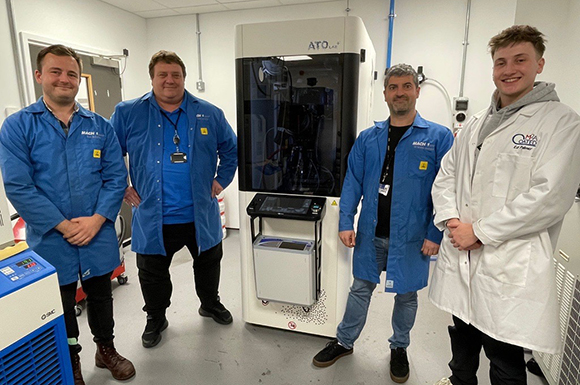

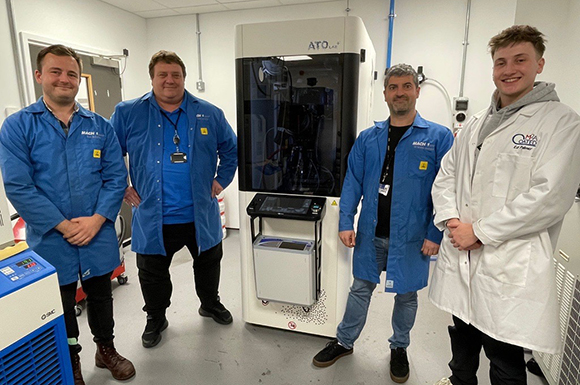

Analytik, a supplier of scientific instruments for a range of applications, based in Cambridge, UK, has reported how Swansea University, Wales, has used an ATO Lab+ atomiser developed by 3D Lab, Warsaw, Poland, to support the university’s work in metal powder production for Additive Manufacturing applications.

Before integrating ATO Lab+ into its alloy development workflow, the Swansea University team faced significant hurdles, stated Analytik. The previous method of developing alloys for Additive Manufacturing involved using external suppliers to gas atomise the powder. This caused delays of approximately fourteen weeks and required a minimum batch size of 200 kg, leading to unnecessary waste. It meant that the team was unable to link its small-scale rapid alloy prototyping and in-house AM capabilities without external powder production.

The ATO Lab+ ultrasonic metal atomiser supplied by Analytik has enabled the Swansea team to swiftly produce small batches of novel alloy powders, for faster, more efficient production within the university’s own lab. This speeds up alloy discovery for a wide range of cutting-edge applications.

Professor Nick Lavery, Director of the Materials Advanced Characterisation Centre (MACH1), and the lead academic of the Swansea Additive Manufacturing Research (SAMR) group, stated, “The ATO Lab+ machine is well manufactured and 3D Lab have been very helpful with all aspects including procurement, installation, commissioning, training and troubleshooting.”

Going forward, Swansea University plans to develop novel alloys for various Additive Manufacturing techniques, including Laser Beam Powder Bed Fusion (PBF-LB), Binder Jetting (BJT), blown powder, and Hot Isostatic Pressing (HIP).

Download Metal AM magazine