Study reviews the status of additively manufactured lattice structures

October 21, 2021

Researchers at the University of Limerick, Ireland, have undertaken a study to establish the current status and opportunities for metal lattice fabrication. Given the prevalence of Additive Manufacturing, and its flexibility in producing complex structures with intricate geometry, the fabrication of lattice structures via the AM process has gained considerable attention in recent years, and can offer performance gains in a growing number of applications.

Designers and researchers have explored, and are still exploring, different strategies to optimise the mechanical properties of these structures. In a paper titled ‘Compressive Behaviour of Additively Manufactured Lattice Structures: A Review’, published in the journal Aerospace, PhD Aeronautical Engineering Candidate Solomon O Obadimu and Senior Lecturer Dr Kyriakos I Kourousis, both at the University’s School of Engineering, reviewed both metallic and non-metallic lattice structure related literature, focusing on the compressive properties and performance.

Lattice structures are composed of repeating unit cells connected by a series of struts and nodes in a three-dimensional space. In addition to their high impact energies absorption, they offer improved strength to weight ratio, the authors explain. Hence, continuing research and development in AM lattices necessitate understanding their compression mechanics, giving AM designers and researchers sufficient information to make informed decisions when designing lattice structures for AM, ensuring that safety is not compromised.

The authors asked questions such as what factors influence the mechanical performance of these structures, what is the current state of AM lattice fabrication, and are there still opportunities in metal lattice fabrication? The study provides a summary of progress to date in AM lattice structures, with a focus on their compressive performance.

Their findings revealed the following key insights, amongst others:

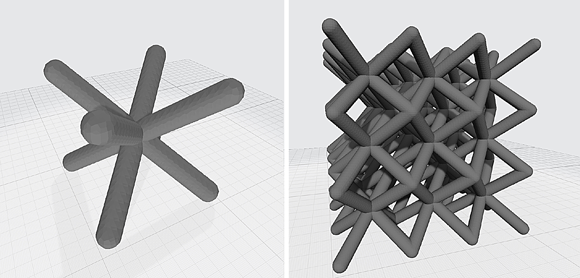

- The most commonly utilised lattice structure model is the body-centred cubic (BCC) structure (Fig. 1)

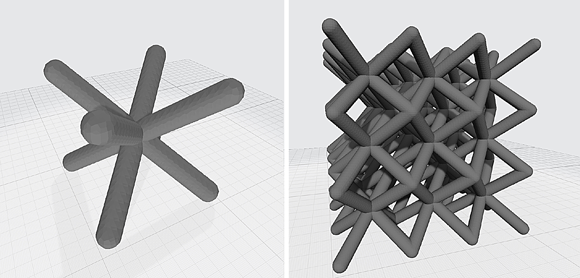

- In terms of optimisation techniques, for metallic lattices, the focus is only on improving design features. For example, adding vertical members (Fig. 2a), such as the BCCZ lattice model and increasing radii corners of a lattice strut (Fig. 2b), such as the GBCC lattice model. On the other hand, for non-metallic optimisation techniques, the focus is on improving process parameters, such as layer height and print angle

- Triply periodic minimal surface (TPMS) and topology optimisation (TOP) are the most utilised lattice optimisation methods for metallic structures. The former is based on mathematical algorithms, while the latter is based on engineering judgement

- Lattice morphology, including cell size and shape, significantly govern the compressive behaviour, as well as the energy absorption capability of lattices. Consequently, even small changes in the morphology can influence the overall behaviour of the structure.

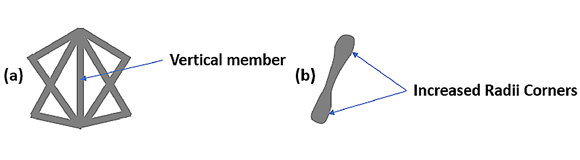

- In terms of challenges, the literature revealed the following, amongst other findings: Research efforts are only geared around Powder Bed Fusion (PBF) for metal lattice fabrication and Material Extrusion (MEX) for fabricating polymer lattices

- The repeatability of AM process and reducing fabrication induced irregularities remain a challenge

- Although finite element simulations have been reported to be in good agreement with experimental results, AM researchers, however, warn that both the former and the latter can underestimate actual in-service mechanical performance of lattices

- Regarding the most commonly utilised AM methods for lattice fabrication, based on the literature reviewed, as shown in Fig. 3, Powder Bed Fusion and Material Extrusion AM methods top the list, the former at 51.92% and the latter at 36.54%. Also, Material Jetting (MJ), Binder Jetting (BJT) and Vat Photopolymerisation (VPP) accounted for 5.77%, 3.85% and 1.92%, respectively.

In conclusion, the authors stated that the challenges highlighted above present an opportunity to further conduct AM related research, especially exploring the fabrication of metal lattice structures via the MEX processes, as well as exploring optimisation strategies by building upon the body of knowledge from PBF metal fabrication.

The full article of this study can be viewed and downloaded for free: Obadimu, S O; Kourousis, K I, Compressive Behaviour of Additively Manufactured Lattice Structures: A Review. Aerospace 2021, 8, 207. https://doi.org/10.3390/aerospace8080207

For more information contact: Solomon O Obadimu Email: [email protected] Dr Kyriakos I Kourousis Email: [email protected] School of Engineering University of Limerick, Ireland