Stryker publishes pre-clinical study on bone in-growth potential of metal AM spinal cages

August 6, 2018

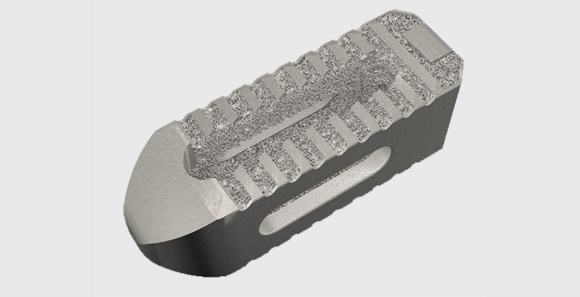

Stryker’s Tritanium PL cage, built using metal Additive Manufacturing (Courtesy Stryker)

Stryker Spine, Kalamazoo, Michigan, USA, has announced the publication of a pre-clinical animal study comparing the performance of interbody spinal cages made of various materials. The results of the study illustrated significant differences in the performance of the company’s interbody implants, with its metal additively manufactured Tritanium® cages showing a reduction in range of motion (ROM) and an increase in bone in-growth profile and construct stiffness.

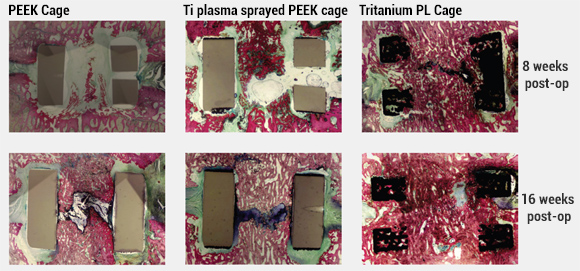

The cages involved in this study included Stryker’s traditional PEEK cages, plasma-sprayed titanium-coated PEEK cages, and Tritanium cages. The results demonstrated that the Tritanium cages exhibited significantly greater total bone volume within the graft window at both 8 and 16 weeks post-surgery compared to the PEEK cages. Tritanium cages were also said to be the only cages to show a decrease in ROM and an increase in stiffness across all three loading directions (axial rotation, flexion-extension, and lateral bending) between the 8 week and 16 week time points.

Bone in-growth in Stryker lumbar interbody fusion cages at 8 weeks and 16 weeks post-op (Courtesy Stryker)

Sigurd H Berven, M.D., Orthopaedic Surgeon at the University of California, San Francisco, USA, and one of the authors of the study, stated, “The results of this study provide an evidence-based approach to decision-making regarding interbody materials for spinal fusion, as there is significant variability in the materials commonly used for interbody cages in spine surgery. The study showed the potential for bone in-growth into and around the Tritanium cages.”

Michael Carter, Vice President and General Manager of Stryker’s Spine division, stated, “Stryker’s proprietary Tritanium Technology, a novel, highly porous titanium alloy material designed for bone in-growth and biological fixation, is based on Additive Manufacturing techniques for orthopaedic surgery pioneered by Stryker over fifteen years ago. This important study reinforces the value of our growing line of Tritanium interbody cages and demonstrates Stryker’s commitment to bringing the latest in advanced technologies to our customers.”

The full study, titled ‘Bony ingrowth potential of 3D printed porous titanium alloy: a direct comparison of interbody cage materials in an in vivo ovine lumbar fusion model’, was published in the July issue of The Spine Journal.