Scientists from DAP and IEHK at RWTH develop powder blends for PBF-LB process

September 1, 2021

Scientists from the Chair Digital Additive Production (DAP) and the Steel Institute (IEHK) at RWTH Aachen University, Germany, have been working on an approach to test and modify the properties of additively manufactured steels.

Specifically looking at alloys that are composed especially for Laser Beam Powder Bed Fusion (PBF-LB) in order to achieve optimum production and application-adapted mechanical and microstructural component properties. The production of such specific PBF-LB alloys using powder blends is reported to be a promising approach: pre-alloyed, already-established powder materials are specifically influenced in their chemical composition by the addition of elementary powders.

DAP and IEHK believe that ‘geometry for free’ and ‘complexity for free’ are the core messages of Additive Manufacturing – even more is possible, however, since microstructural and mechanical component properties can also be adapted to later application requirements through targeted compositions of the powder material. For this purpose, PBF-LB uses pre-alloyed powder materials currently. Even if these materials are already established in some powder-based AM processes, they are not specifically developed for PBF-LB and have a corresponding optimisation potential. This is where the so-called Rapid Alloy Development (RAD) comes in: Pre-alloyed powder materials are used, among other things, as a starting base and are purposefully modified by adding elemental powders in order to be efficiently optimised for PBF-LB processing – powder blends are created.

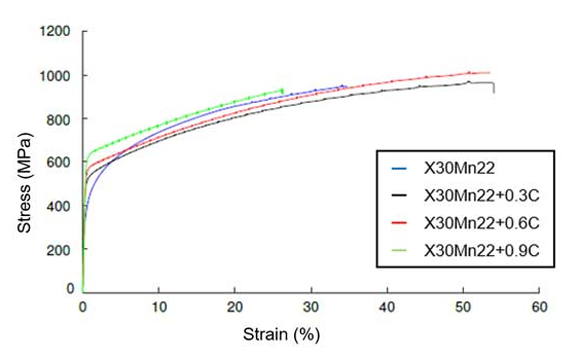

In the application example of the DAP and IEHK, the researchers modified the properties of a pre-alloyed steel powder (X30Mn22) by precisely adjusting the carbon content (C). Carbon has a major influence on the processability of the material in the PBF-LB process as well as the tensile strength and elongation at break of the additively manufactured components. To investigate the properties of different powder compositions, powder blends consisting of X30Mn22 powder and carbon powder of different proportions were qualified for the PBF-LB process (up to 1.2 wt% C); a relative density of >99.8% was achieved for all compositions.

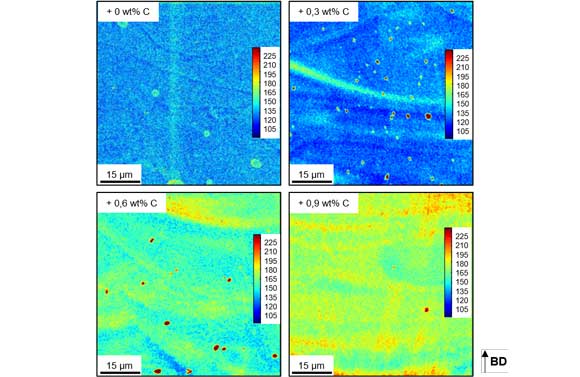

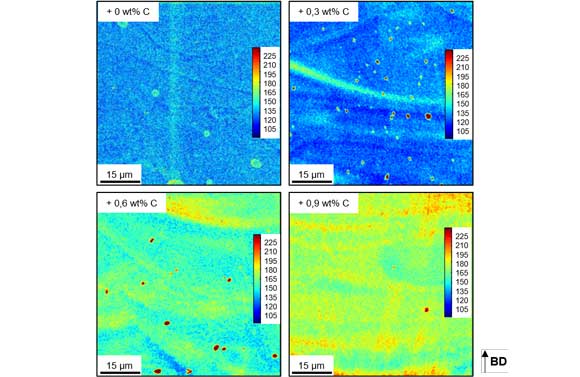

After successfully qualifying PBF-LB for processing the powder blends, further samples were manufactured for the analysis of microstructure and mechanical properties. An electron beam microanalysis showed that the carbon was evenly distributed in the matrix and, thus, transitioned into the alloy. In addition, the scientists compared the behaviour of the samples produced from powder blends with the known properties of the samples made from pre-alloyed steel powder of the initial composition. Tensile tests for the analysis of the mechanical properties proved the successful adaptation of the powder material properties: the tensile strength, as well as the elongation at break, vary according to the addition of the amount of carbon.

DAP and IEHK state that the results of its application development show that the RAD approach of using powder blends is a promising approach for a fast and resource-efficient qualification and development of PBF-LB-optimised alloys. In addition, the chemical alloy composition can be adjusted by means of this approach in order to specifically influence and reproduce the microstructural and mechanical properties of the components to be additively manufactured.

In the future, the mechanical behaviour of actual components made from PBF-LB-optimised powder blend alloys are up for more detailed investigation by DAP and IEHK. In addition, their properties are compared with those of components made exclusively from pre-alloyed powder in order to identify further potential benefits.

This research project is funded by the German Research Foundation and the Federal Ministry of Education and Research.