SBI International to supply Multistation with its metal AM machine M3DP

May 11, 2020

SBI International, Hollabrunn, Austria, and Multistation SAS, Paris, France, have entered into an exclusive partnership to deliver Plasma Arc metal Additive Manufacturing to the French market. As part of the partnership, SBI will supply its metal wire and arc Additive Manufacturing M3DP technology.

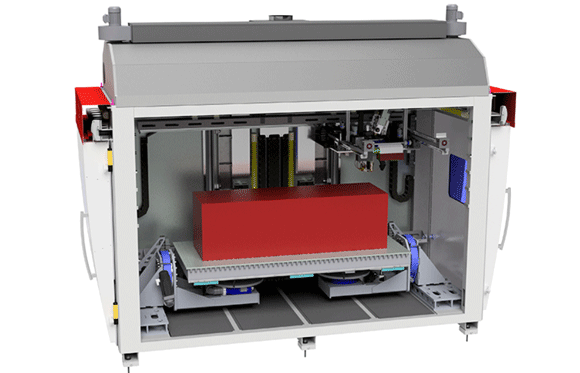

The M3DP features a modular and compact design, with a broad application range suited for plasma arc metal Additive Manufacturing in industries such as aerospace, oil & gas, marine & shipbuilding, tool making, service and maintenance applications. It is said to be capable of achieving high deposition rates, which benefits the manufacturing of large parts. Its optional gas-tight working chamber offers the possibility to process also sensitive materials like titanium and nickel-base alloys.

“We are very happy that we can introduce our new M3DP product range to the French market, which is particularly dedicated for Additive Manufacturing in aerospace applications,” stated Dr Martin Peruzzi, CEO of SBI. “The experience of Multistation in the field of Additive Manufacturing will support the introduction of our M3DP product range into the French industry.”

Yannick Loisance, CEO of Multistation, commented, “With the M3DP line of SBI, we complete our offer of metal Additive Manufacturing processes with a very powerful process, complementary to our different offerings in laser or electron beam bed melting, supersonic or BinderJetting and DED ( WAAM, laser wire, LMD). Having SBI as our partner we can now offer a complete portfolio of solutions along the value chain of metal Additive Manufacturing.”