Ricoh and Siemens aim to industrialise aluminium Binder Jetting for mass production

November 7, 2023

Ricoh Company, Ltd, and Siemens Digital Industries Software are collaborating to advance the use of aluminium Binder Jetting (BJT) for mass production. Under the partnership, Ricoh is leveraging Siemens’ Additive Manufacturing Network capabilities to maximise the efficiency of the process and to achieve the scale required to take advantage of BJT in an industrial setting.

Ricoh will also implement Siemens’ Additive Manufacturing Network in an effort to optimise the aluminium BJT workflow for production preparation, planning, scheduling, and production management. The company has also implemented Siemens’ Brownfield Connectivity (BFC) and has begun collecting and storing information on each process necessary for quality stabilisation and production control.

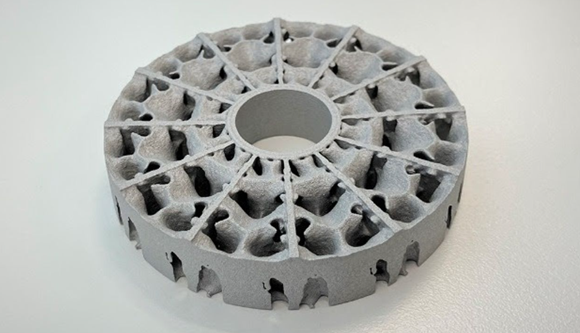

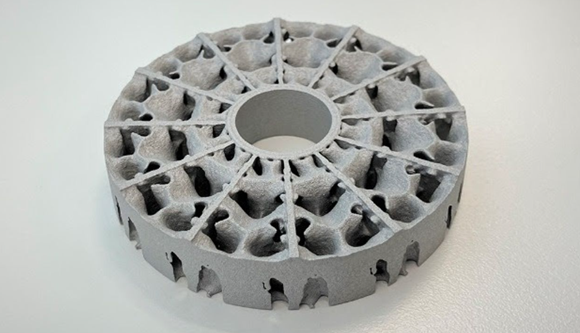

Ricoh’s Binder Jetting process applies the company’s inkjet printing technology and expertise to enable the production of complex metal parts that would not be possible with conventional metal processing methods such as machining and casting. Siemens will continue to provide Ricoh with solutions optimised for the aluminium BJT workflow, and both companies aim for early commercialisation of these technologies.

“The production of aluminium parts is a holy grail for the additive industry and we’re delighted that Ricoh has chosen Siemens’ Additive Manufacturing Network capabilities from the Siemens Xcelerator portfolio of industry software to help them commercialise a much sought-after process,” stated Zvi Feuer, Senior Vice President, Digital Manufacturing Software, Siemens Digital Industries Software. “Our collaboration with Ricoh will apply its expertise in Additive Manufacturing with our knowledge and experience in delivering additive-specific operations management technology across a wide spectrum of industries – from order capture, production planning, and manufacturing to part delivery transaction closure. Together, Siemens and Ricoh are working to deliver repeatability and consistency at the scale needed to truly take advantage of using robust and repeatable aluminum additively manufactured parts in the commercial world.”

Tokutaro Fukushima, General Manager of Additive Manufacturing Business Center, Ricoh Futures Business Unit, Ricoh Company, Ltd., added, “Ricoh will enable our customers to manufacture innovative aluminium components that have never been produced before by any process and will work with them to realise new customer value in the area of electrification of EVs and other forms of mobility. By combining Siemens’ powerful solutions and knowledge with Ricoh’s aluminium BJT, we will be able to provide our customers with highly reliable and practical systems for mass production applications. We hope to promote electrification together with our customers and contribute to solving social issues such as realizing a zero-carbon society.”

Both Ricoh and Siemens will exhibit at this year’s Formnext, held at Messe Frankfurt, Germany, November 7 to 10, 2023.

Visit Ricoh on booth H12.0 B33

Visit Siemens on booth H12.1 D119

https://additive-manufacturing-network.sws.siemens.com/

Download Metal AM magazine