Researchers additively manufacture defect-free multi-material structures

April 18, 2024

Researchers from ETH Zurich, Switzerland, and Aerosint, Herstal, Belgium, recently published a paper in Materials & Design focusing on the defect-free Additive Manufacturing of CuCrZr-316L steel multi-material structures.

Whilst multi-material Laser Beam Powder Bed Fusion (PBF-LB) offers new design opportunities, balancing — possibly large — thermal, physical or elastic property differences to avoid defects is challenging. Combing Cu alloys with stainless steel, for example, is appealing for components which require high thermal/electrical conductivity in some areas and high strength and corrosion resistance in others.

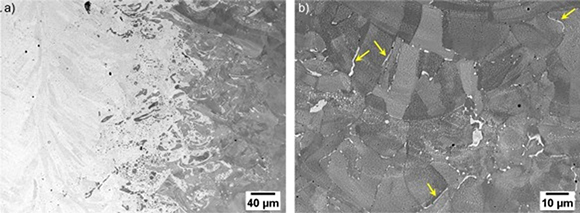

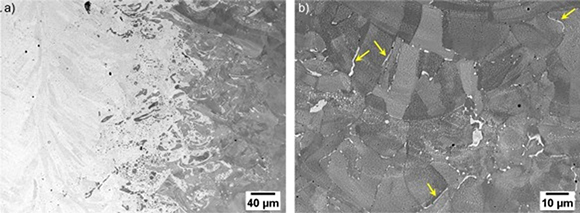

In the paper “Coupling hot isostatic pressing and laser powder bed fusion: A new strategy to manufacture defect-free CuCrZr-316L steel multi-material structures,” CuCrZr-316L samples were fabricated with a recoater allowing for deposition of two powders within a layer. As-built samples exhibit significant intermixing and two types of defects: porosity in CuCrZr and steel cracking near the interface. Subsequent Hot Isostatic Pressing (HIP) effectively addressed these issues by closing pores and healing cracks.

Despite an overall softening, CuCrZr stays harder near the interface thanks to a very fine-grained structure retained after HIP. Alternatively, when CuCrZr powder near the interface is left unmelted and subsequently sintered, regions with small equiaxed grains and Cr-rich precipitates are formed, which exhibit properties similar to those of additively manufactured and HIPed CuCrZr. Hence, locally leaving powder unmelted and sintering it proved to be a successful strategy for producing defect-free 316L-CuCrZr components via PBF-LB, provided an airtight enclosure is ensured.

The full paper is available for free here.

Download Metal AM magazine