Relativity Space and US Air Force Research Laboratory partner to explore real-time flaw detection

April 17, 2024

Relativity Space, based in Long Beach, California, USA, has secured an $8.7 million contract with the US Air Force Research Laboratory (AFRL) to explore real-time flaw detection in Additive Manufacturing.

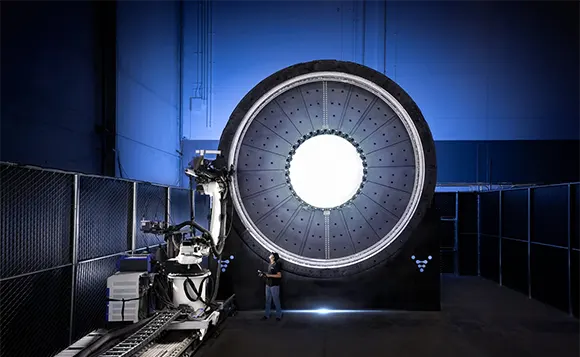

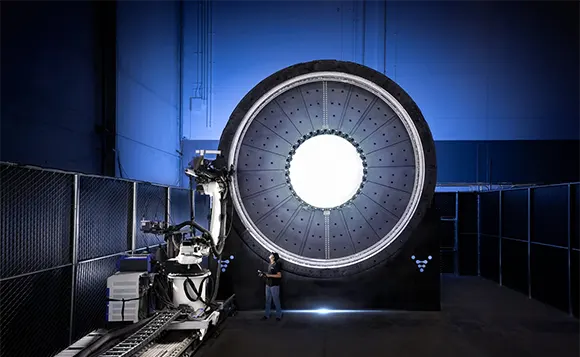

The two-year research contract is from the AFRL’s Materials and Manufacturing Directorate at Wright-Patterson Air Force Base in Ohio, USA. The project will be completed using Relativity’s Stargate 3D AM platform at their factory in Long Beach, California.

In a statement to SpaceNews, Adam Hicks, a physicist at AFRL’s Materials and Manufacturing Directorate, shared, “This effort with Relativity Space is in response to a congressional demand signal.”

Congress in the National Defense Authorization Act directed the US Defense Department to study how Additive Manufacturing can be utilised to accelerate the production of aerospace components and vehicles. Additionally, lawmakers have mandated that the Department of Defense establish a network of domestic suppliers to help evaluate these technologies.

Hicks said AFRL will work with Relativity on real-time flaw detection in large-format Additive Manufacturing, “The intent is to explore various in-situ process monitoring and post-build non-destructive evaluation techniques, along with advanced robotics, automation and digital enterprise tools.”

“Relativity Space will develop and prove a real-time flaw detection system which will detect, localise and classify defects during the print process,” Hicks continued. “This data will then be aggregated, enabling a true digital thread.”

Experts believe real-time flaw detection can be crucial for larger-scale adoption of Additive Manufacturing in spaceflight and other demanding applications.

Download Metal AM magazine