Registration opens for AKL’22 International Laser Technology Congress

December 1, 2021

Registration is now open for AKL’22, International Laser Technology Congress, organised by Fraunhofer Institute for Laser Technology (ILT). The conference will take place May 4–6, 2022, in Aachen, Germany, with all presentations simultaneously in English or German.

In addition to the core conference, the first day will be dominated by parallel expert forums that will dive deeply into the production topics of Additive Manufacturing, process monitoring and digitalisation. For the first time, Fraunhofer ILT will also be devoting itself to photonic issues in quantum technology, a new field that is expected to have a long-term impact on digitalisation issues in production technology, such as the management of big data and Artificial Intelligence (AI).

The spectrum of research aspects in the field of AI ranges from machine learning in industrial practice to the use of augmented reality and data analysis with neural networks. However, AI is only a small component in the expert forum ‘Process Monitoring & Digitalization’, which will focus on quality control and optimisation of various laser manufacturing processes such as cutting, welding and AM.

Participants of the expert forum ‘Laser Additive Manufacturing’ will have the opportunity to spend the entire day learning about AM technologies. Initially, the focus will be on Laser Material Deposition (LMD); in addition to the question of rapid alloy development, the workflow in laser material deposition will be examined in its entirety. Participants will also learn how extreme high-speed laser deposition welding process (EHLA) has evolved into EHLA 3D.

The second part of the forum will focus on Laser Beam Powder Bed Fusion (PBF-LB). For AM to achieve a breakthrough in the manufacturing industry, the entire data chain must be considered. Experts will also shed light on simulation tools, process control systems and concepts for increasing productivity.

Quantum technologies are currently being advanced internationally at a cost of billions, beginning a technical revolution that may enable fundamentally new applications. These include quantum imaging, quantum communication and quantum computing. In the expert forum ‘Quantum Technology’, interested parties can gain insight into the current state of research and development. Among other things, this forum will highlight quantum-safe encryption for optical networks and frequency standards for quantum applications as well as the use of quantum technology for inline monitoring.

At the Technology Business Day, managing directors, marketing managers and strategists will receive an overview of the laser markets in Europe, Asia and America with an in-depth look at technological trends in individual areas such as e-mobility, micro-manufacturing and AM.

For laser newcomers, Fraunhofer ILT is also offering the Laser Technology ABC’s seminar on May 4, 2022. There, companies with little or no experience in laser technology will receive a structured, hands-on overview, from the selection of suitable beam sources and handling systems for various applications to safety aspects in industrial laser technology.

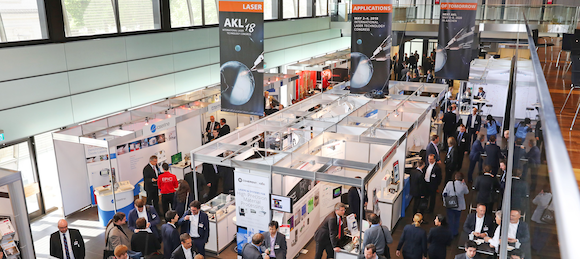

In addition, over forty speakers from industry and science will shed light on the current state of laser technology in the field of macro and micro laser material processing, as well as laser beam source development on May 5 and 6, 2022. All AKL‘22 participants will also have the chance to make contact with around forty component and system manufacturers at the sponsors’ exhibition accompanying the conference.

Alongside Fraunhofer ILT, AKL’22 is supported by the European Commission, the European Photonics Industry Consortium EPIC, OptecNet Deutschland and the industry associations SPECTARIS, VDA, VDMA and VDI Technologiezentrum.

Registration is now open through the International Laser Technology Congress website. Those who register prior to March 4, 2022, will receive a 10% discount from ticket prices.