Hybrid Manufacturing Technologies, TWI & PSL to revolutionise cold plate manufacturing

May 27, 2022

UK-based Hybrid Manufacturing Technologies (HMT), The Welding Institute (TWI) and PSL Assemblies Ltd (PSL) have partnered to launch the SubSurface project with the aim of maturing a technology that is claimed to revolutionise cold plate manufacturing.

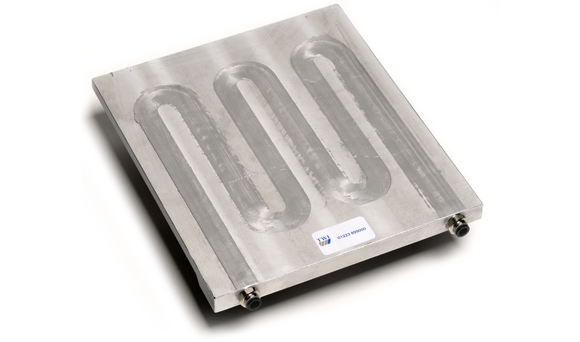

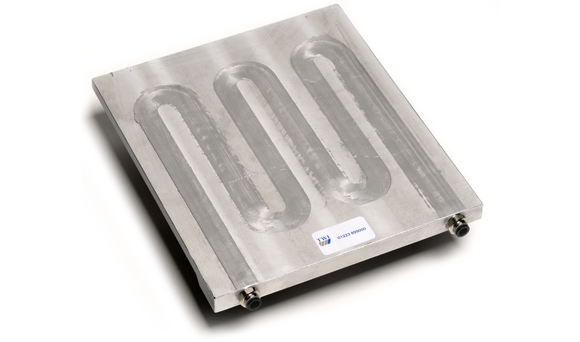

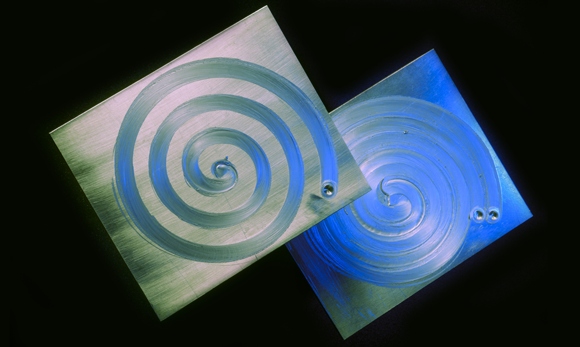

Currently, the cold plate manufacturing process is said to be slow, costly and complicated, often resulting in poor yields due to quality issues. However, CoreFlow™, a patented technology developed by TWI in 2016, could offer a solution to this. CoreFlow is a solid-state process derived from friction stir welding that creates sub-surface networks within metal structural elements. Integrating this approach into a hybrid CNC could overcome the cold plate manufacturing challenges by enabling the production of cold plates in a single setup.

Although early work has demonstrated the potential of the CoreFlow process, this has been on dedicated R&D friction stir equipment, which is not representative of the platforms typically found in the industry.

The CoreFlow technology enables sub-surface networks within metal structural elements, which enables production of cold plates in a single setup (Courtesy HMT)

Under the SubSurface project, the partners will develop a new process head that allows CoreFlow to be retrofitted to any CNC system. In addition to the ability to alternate between milling and CoreFlow, the hybrid CNC is also expected to feature optional subsurface inspection using the AMBIT™ WAVE ultrasonic inspection head developed by HMT.

“We are pleased to be working with TWI and PSL to align our collective technical prowess and market knowledge,” stated Dr Jason Jones, founder & CEO, HMT. “Together, we will deliver a step change in capability and improved cost effectiveness for the next generation of thermal management solutions.”

Leveraging the wide availability of CNC milling machines, it is expected the SubSurface solution could be adopted at a fraction of the current costs, with capital investment said to be around five times less than that for current methods.