PostProcess collaborates with Lillbacka Powerco on automated surface finishing for metal AM

October 19, 2020

PostProcess Technologies Inc., Buffalo, New York, USA, is collaborating with Finnish-based Lillbacka Powerco Oy, a manufacturer of crimping machines, to provide an automated surface finishing solution for metal additively manufactured parts.

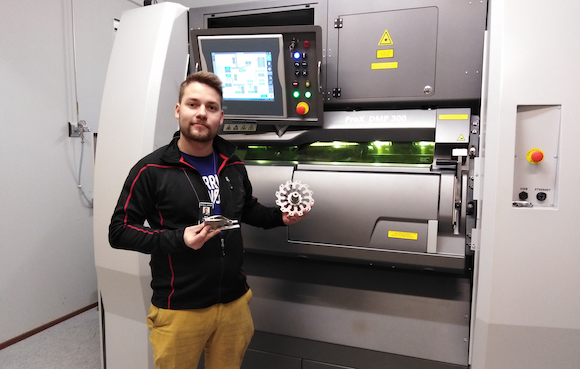

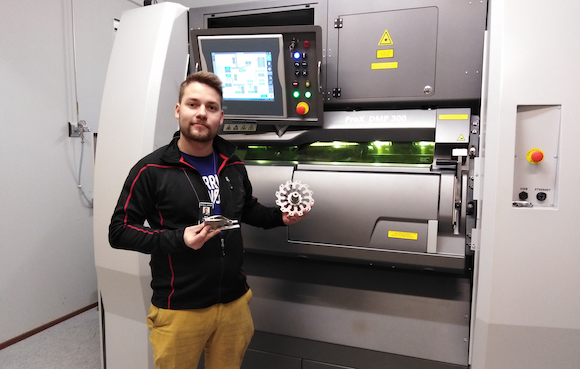

To enable faster lead times and increase digitalisation within the company, Lillbacka Powerco uses Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing in its production. Specifically, PBF-LB is used to produce the end-use crimping dies for each machine, as well as for custom tooling requests.

The company has found traditional blasting procedures to be time-consuming, and will now implement the PostProcess RADOR™ automated surface finishing solution to achieve the desired finish on its crimping dies. The RADOR uses PostProcess’s Suspended Rotational Force (SRF) technology to consistently finish parts from all AM technologies to customer specifications via optimised energy with vertical motion and proprietary consumables.

The full-stack solution has been developed for use with all AM technologies and won’t break delicate parts. It also incorporates noise-reducing features for low dBA to prevent disruption in non-production environments.

Masi Tammela, Additive Manufacturing Manager at Lillbacka Powerco, stated, “As we further implement digitalisation within our product portfolio, we have come to realise the power in leveraging intelligent solutions in our own manufacturing processes. Bringing the automated RADOR into our additive workflow will allow us to broaden our additive capabilities, from prototyping and custom tooling to serial production of customer-specific crimping dies.”

Bruno Bourguet, Managing Director at PostProcess Technologies, added, “We’re pleased to see the efficiencies that the RADOR will unlock for a company as prestigious and longstanding as Lillbacka. We are confident that this software-driven solution will continue to prove advantageous to Lillbacka’s workflow and bolster their ability to print with the high-quality standards that they are known for.”