Polygonica to showcase its new anisotropic offsetting at Rapid + TCT 2019

May 9, 2019

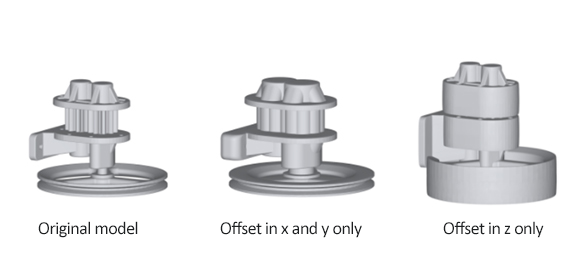

Pump design highlighting anistropic offsetting (From mark22973268 as published on Thingiverse. Courtesy MachineWorks Ltd)

Polygonica, a software toolkit for processing polygon meshes developed by MachineWorks Ltd, Sheffield, UK, will showcase its range of additively manufactured polygon capabilities at Rapid + TCT 2019 in Detroit, Michigan, USA, from May 20-23. The capabilities showcased by the company will include its the Anisotropic Offsetting, where a solid can be offset in different directions – each with their own value.

The company states that, along with performance improvements to laser scan meshing and hole-filling, a new hole-fill algorithm has been added to identify and reconstruct dental margin lines from low-quality scans. The Polygonica team stated that it is continuing to work on improving hole-filling through better feature recognition on noisy scan meshes and performance and quality improvements to the adaptive shrink wrapping algorithm.

Shrink wrapping removes internal detail and can reportedly produce a close-fitting watertight envelope around arbitrary geometry including sparse point datasets. Other uses include generating proxy level of detail meshes for use in VR/AR and accelerating clash detection by providing a tighter envelope than is possible with convex hulls.

Polygonica’s Software Toolkit supports advanced healing, Booleans, offsetting, remeshing, feature detection and simplification. It is used in a range of leading Additive Manufacturing and scanning applications including 3D Sprint, 3DXpert and CimatronE from 3D Systems, GrabCAD Print from Stratasys, Spaceclaim and Discovery Live from Ansys, Fabricate, Live Parts and Fab Flow from Desktop Metal, Simpleware from Synopsys, Converge Studio from Convergent Science and Renishaw’s Adept and Dental Manufacturing System.

Richard Baxter, Sales Manager for Polygonica, stated, “Our Polygonica customers benefit from MachineWorks’ 25 years of developing advanced polygon-based technology. Integrating Polygonica into their applications not only reduces costs and time to market but reduces the demands of ongoing maintenance and bug-fixing allowing their development teams to focus on adding unique value to their workflows. Every year we are providing more and more polygonal mesh design functionality, allowing our customers to build advanced polygon-editing workflows without the time-consuming and expensive requirement to reverse-engineer back to CAD.”