Optisys uses SLM 500 to manufacture parts for space

June 14, 2021

Optisys, an advanced turnkey antenna and radar product supplier headquartered in Salt Lake City, Utah, USA, is reported to be using its SLM®500 Additive Manufacturing machine from SLM Solutions, Lübeck, Germany, in the production of a range of high-strength metal components used in space missions.

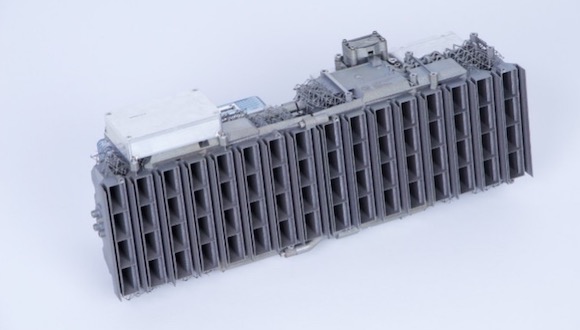

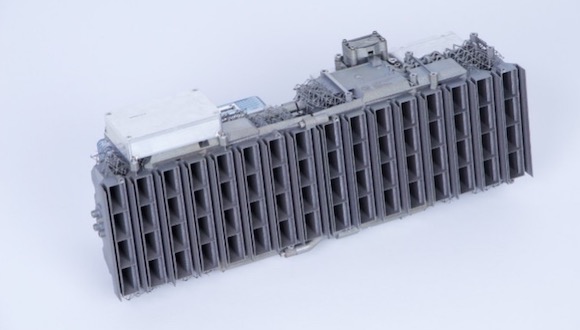

Optisys has customers which rely on a broad spectrum of solutions, including feeds, slotted flat panels and phased arrays used in applications ranging from sea to outer space, and is using topology optimisation to produce light, compact and robust designs, built to withstand these harsh conditions.

“We are a company that wouldn’t exist without Additive Manufacturing,” stated Janos Opra, Optisys CEO. “The SLM 500 gives us exactly what we need, for example, to manufacture antennas used on space missions.”

To do this, the components produced must be able to withstand the harsh conditions of the entire range of space environments from Low Earth Orbit (LEO) to deep space probes. Opra continued, “The atomic oxygen in the atmosphere virtually sandblasts the parts. They also must withstand high heat loads, and extreme temperature cycling, on other planets. The SLM parts are not only lightweight, but they can also manage harsh conditions and are particularly robust with excellent performance.”

Compared to traditional manufacturing methods, Additive Manufacturing can produce lightweight components by integrating internal hollow structures while maintaining a consistently high component quality. Even small reductions in weight, through component integration, can lead to cost advantages through a reduction in launch costs (these are priced per kg and are a major cost driver for space companies). Due to these unique advantages and the pressure to keep costs to a minimum, conventional manufacturing methods are hardly an option for major players in the space industry.

“Additive Manufacturing technology ensures we can create the lightest, strongest and best performing RF products available,” added Opra. “By coupling large aspects of the RF system into single components or repeatable tiles, our customers can reduce weight enormously over competing suppliers. This is of prime importance for many players in the ‘New Space’ market particularly.”

The SLM 500 is a multi-laser system with up to four 700W lasers working simultaneously. It features closed powder handling with automated powder sieving and supply during the build process without any powder contact. The ability to change the build cylinder is reported to minimise machine downtime, maximise productivity and reduce cost per part. Due to a smart assembly in the build envelope, Optisys produces several individual components in one build process with this machine – something impossible with conventional manufacturing methods.

Sam O’Leary, CEO of SLM Solutions, stated, “We are proud that metal-based Additive Manufacturing is making such an important contribution to space missions. This deployment demonstrates how robust the parts produced with SLM technology are. Innovative, top-tier companies such as Optisys continue to drive Additive Manufacturing forward and bring it to other planets. It makes us proud to enable their success.”