Optical coherence tomography used in process monitoring of Additive Manufacturing

September 1, 2016

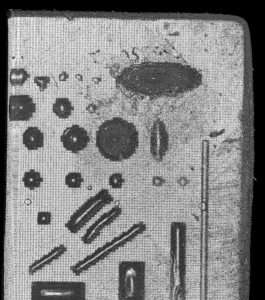

OCT surface projection of a component formed by Additive Manufacturing

Process monitoring in the Additive Manufacturing process has been the recent focus of researchers at Fraunhofer IKTS, Dresden, Germany. The team, led by Dipl .-Ing. (FH) Christian Wolf, have for the first time ever applied the medical imaging technique of optical coherence tomography to monitor the Additive Manufacturing process.

Optical coherence tomography (OCT) has been utilised for in-line monitoring, with analysis of surfaces as well as internal structures of different materials being possible. In the processing of metals (for example with laser cladding), OCT is restricted to surface imaging, but for other materials, it is also capable of revealing internal structures and detecting defects, such as delamination or inclusions.

The process, for example, allows for examining the adhesion of the individual layers in 3D-printed ceramics to be examined. By adding other optical technologies, such as Raman spectroscopy, it is possible to monitor additional process characteristics, such as the degree of cure during the curing process for plastics.

Ultrasonic technology has traditionally been used primarily for non-destructive testing of metal parts, such as hollow shafts, but it can also be used in additive manufacturing. Particularly when water baths are used for 3D printing of ceramic components, application of ultrasonic technologies for reliable detection of pores and delamination is practical. With ultrasonic technology, it is also possible to detect defects in additively manufactured metals.

The different technologies developed and used at Fraunhofer IKTS focus on in-process measurements to allow defects to be detected and segregated, and the necessary process adjustments to be made during the manufacturing process. This makes the Fraunhofer IKTS testing technologies the key to achieving highly efficient certified AM systems. Continuous monitoring of different AM processes is an important basis for transfer to industrial-scale production and for ensuring consistent product quality.