Open Additive and Addiguru partner to expand powder bed analytics

May 25, 2022

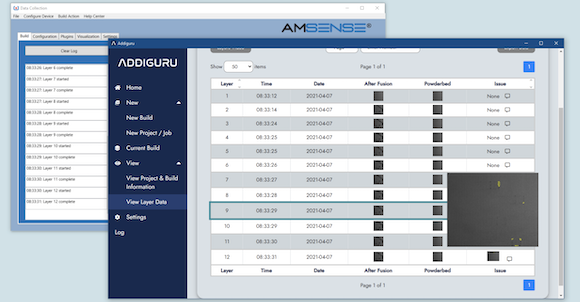

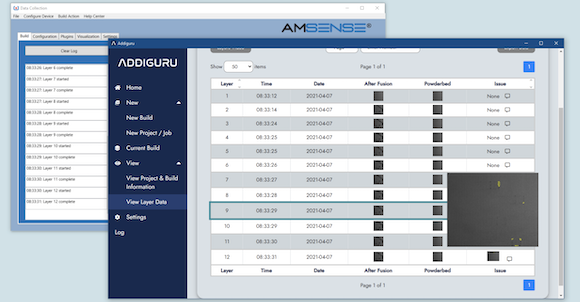

Open Additive, LLC, Beavercreek, Ohio, USA, and Addiguru, LLC, Metairie, Louisiana, have announced an agreement to provide Addiguru’s Recoater, a Laser Beam Powder Bed Fusion (PBF-LB) analysis software, as a plugin to Open Additive’s AMSENSE® multi-sensor data collection and analysis platform.

AMSENSE is a modular hardware/software platform which captures layer-by-layer data of the PBF-LB process in real time during the build. When joined with the Recoater plugin – which utilises computer vision, artificial intelligence, and machine learning to identify critical process errors in real-time – the collected data is processed to provide a layer-by-layer recoat analytical interpretation of the captured data. Together, these two capabilities are hoped to represent the state-of-the-art in real-time Additive Manufacturing machine monitoring and process controls.

Since its introduction in 2018, AMSENSE has sold various configurations for use on its own PANDA™ machines and other industrial PBF-LB Additive Manufacturing machines. Addiguru provides process insights and reduced production costs for Additive Manufacturing service bureaux and other users across several important industrial machines. The software has been commercialised and has multiple installs in the industry.

“I am pleased with the Addiguru collaboration on AMSENSE and look forward to working closely with Addiguru to bring this new analytic to market especially with the actionable information that Addiguru’s Recoater Plugin will provide to additive manufacturing systems users and researchers alike,” stated Joe Sciabica, Managing Member, Open Additive.

Shuchi ‘SK’ Khurana, founder, Addiguru, added, “Addiguru recognises the high added costs of part development and production due to lack of useful process insights and controls, and we’re excited to work with Open Additive to bring practical and affordable solutions to the metal Additive Manufacturing industry to address this problem.”