nTopology and EOS collaborate to eliminate the need for STL files in AM

September 13, 2019

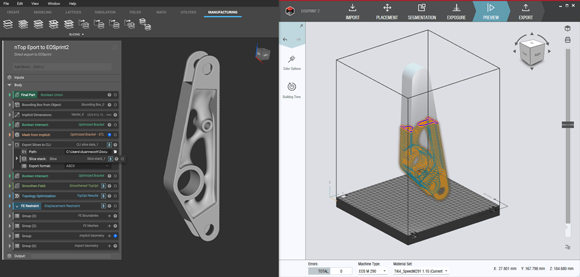

nTopology, New York City, USA, and EOS, headquartered in Krailling, Germany, have collaborated to advance Additive Manufacturing software capabilities with end-to-end integration at the slice file level, so that engineers can move from the design stage of a project directly to manufacturing on EOS systems without the need to convert their designs to the STL file format or use third-party software for build preparation.

This means significantly less discretisation and allows for the design parameters of lattice structures, feature details, localised and simulation-driven material properties resulting in the ability to design at the macro, meso and micro scale. This limits variations and adjustments between the design and the built part, saving design time and non-value adding engineering time spent working with third-party software, as well as preventing loss of data with large STL files.

Duann Scott, Director of Business Development and Partnerships at nTopology, explained, “Working with the EOS software team has enabled us to create a direct workflow between nTopology software and EOSPRINT that allows our shared customers to realise their designs faster and more reliably.”

“Eliminating the need to use the dreaded STL and 3rd party software in turn eliminates loss of data in translation and costly human errors. The Additive Minds team are crucial to our partnership, in giving us valuable feedback as well as working together on projects to ensure our customer’s success,” he concluded.