nLIGHT, Optoprim and TUM collaborate to push the limits of powder bed fusion processes

June 10, 2021

nLIGHT, Inc., Vancouver, Washington, USA, launched the AFX-1000, a programable high-power fibre laser, in November 2020. The laser has the ability to switch between a single-mode beam and other beam profiles without the use of free space optics, said to make the AFX-1000 an ideal beam source for applications in Additive Manufacturing processes.

In order to demonstrate the potential of the new beam profiles in powder bed fusion processes, nLIGHT and Optoprim collaborated with the Professorship of Laser-based Additive Manufacturing by Prof. Dr.-Ing. Katrin Wudy at Germany’s Technical University of Munich (TUM).

Some of the fundamental research questions for investigations with the AFX-1000 targeted in the collaborative effort include identifing which beam profiles enable an increased melt pool size combined with a smooth melt pool. The team will look at how the spatial change of the beam profile influences the temperature gradients and microstructure.

The collaboration will also identify which processing strategies lead to process acceleration and simultaneous stabilisation.

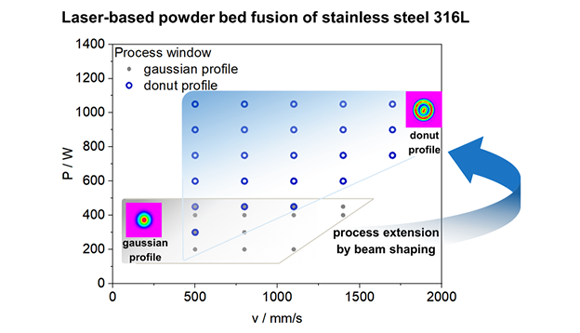

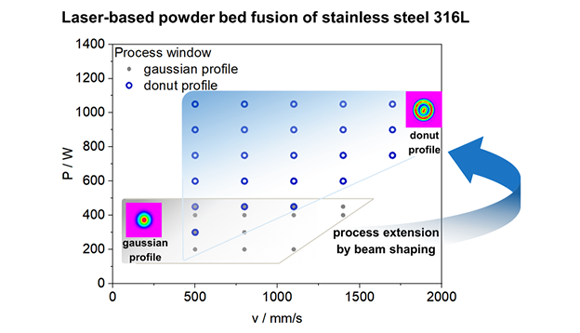

To date, experiments with the nLIGHT beam source highlight the potential for widening and smoothing the melt pool, as well as increasing process speed with the donut profiles.

“This approach will change the way we use Additive Manufacturing with metals. It gives us the ability to tailor laser-based processing regarding faster and optimal processing conditions as well as the microstructure of parts e.g. through larger melt pools,” stated Prof Wudy. “We are excited to push the barriers of Additive Manufacturing with our partners of nLIGHT and Optoprim in the years to come.”