nLIGHT launches programmable laser for metal AM

November 20, 2020

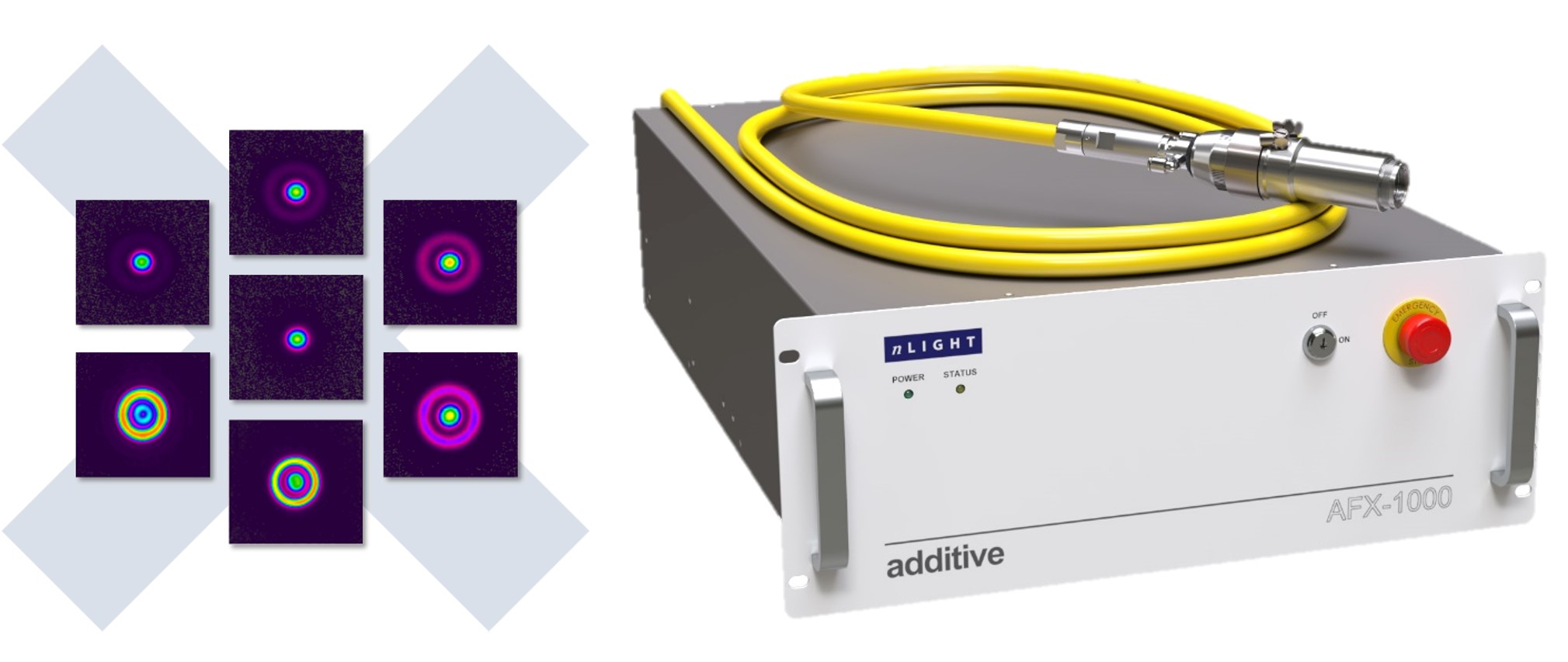

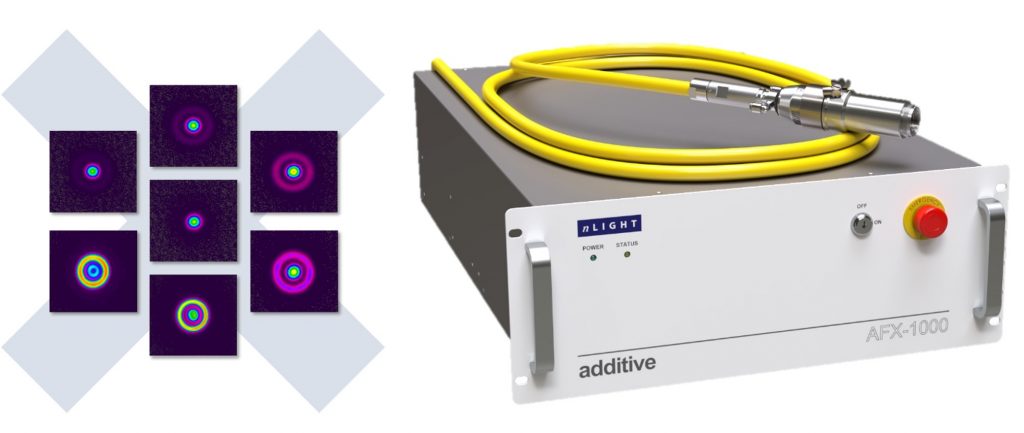

nLIGHT, Inc., Vancouver, Washington, USA, a provider of high-power semiconductor and fibre lasers for industrial, microfabrication, aerospace and defence applications, has launched the AFX-1000 for the Powder Bed Fusion (PBF) metal Additive Manufacturing market. This programmable high-power fibre laser can switch between a single-mode beam and other beam profiles without the use of free space optics.

The company states that the AFX ring mode geometry stabilises large melt pools, reducing the amount of soot and spatter in the build chamber to improve material quality and production yields.

Discrete AFX beam profiles can be selected on-the-fly as quickly as thirty times per second, offering new degrees of freedom to control melting and solidification rates, physical microstructure and thermal strain that can lead to stress fractures, a frequent cause of part failure. Ring mode processing with a single AFX laser has been shown to produce fully-dense material (> 99.5%) at build rates exceeding 100 cm3/hr with a single laser.

“The AFX-1000 is the world’s first single-mode fibre laser with the beam shaping function performed entirely inside the laser,” commented Rob Martinsen, nLIGHT CTO and General Manager for Additive Manufacturing. “Developed for Additive Manufacturing, AFX enables OEMs and end-users to significantly improve build rates, thereby reducing cost per part.”

“We expect AFX to fundamentally change the economics of AM and to promote broader adoption for series production,” he concluded.