NanoSteel takes first place for its L-40 ferrous alloy powder

May 1, 2018

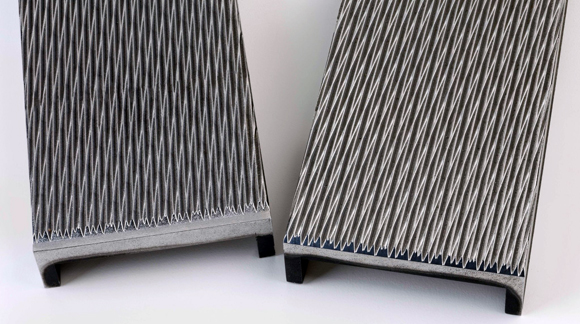

An industrial tool and die set produced from NanoSteel’s BLDRmetal L-40 ferrous alloy powder on a laser PBF system (Courtesy NanoSteel)

The Additive Manufacturing business unit of NanoSteel, Providence, Rhode Island, USA, has been awarded first place in this year’s Rapid + TCT ‘Innovation Auditions’ for its BLDRmetal™ L-40 ferrous alloy powder, designed for use in Powder Bed Fusion (PBF) Additive Manufacturing.

At Rapid + TCT, held in Fort Worth, Texas, USA, April 23-26, 2018, the Innovation Auditions saw eight companies present their selected technology in a five minute audition. Following this initial audition process, a panel of industry judges selected two finalists to present their technology at a keynote session the following morning, with the winner selected by the audience.

NanoSteel’s BLDRmetal L-40 is a ferrous alloy powder that can be printed at room temperature using PBF on commercial equipment to form parts with a unique combination of high hardness and ductility.

According to NanoSteel, BLDRmetal’s lack of processing limitations and excellent physical properties make L-40 attractive for use in several applications, including tooling and die, where hard, ductile alloys are desired for longevity and production efficiency. With the standard turnaround time for traditional tooling and die manufacturing being at least six weeks, L-40 reportedly makes the on-demand AM of tooling and dies easier, enabling fast innovation and cost savings.