MTU Aero Engines establishes new team to focus on Additive Manufacturing for aerospace

May 22, 2018

MTU’s Dr Jürgen Kraus, Director, Additive Manufacturing, will lead the new department (Courtesy MTU)

MTU Aero Engines, Munich, Germany, has established a new department dedicated to Additive Manufacturing for aerospace applications. Led by Dr Jürgen Kraus, the department is staffed by around thirty professionals from various technical disciplines including design engineers, structural mechanics engineers, process specialists and operations scheduling experts.

According to Lars Wagner, MTU’s Chief Operating Officer, the department aims to “maintain and build [the company’s] competitive edge,” and accelerate the development of AM technologies “by pulling all activities – from design to technology development and all the way to production – together in one unit.”The team is said to be looking into new conceptual designs for applications and constructions from a bionics viewpoint, with the aim of pushing the development of the production technology forward and industrialising the entire process chain.

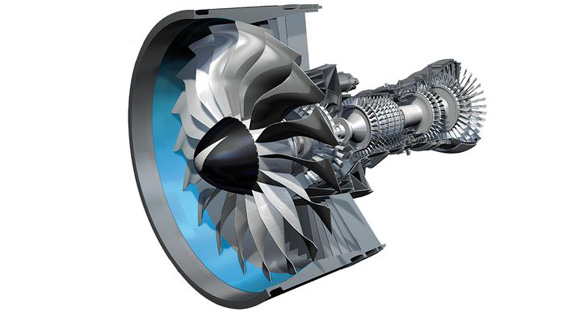

“With the development of new machine types and improved online process control, it will be possible to produce an increasing number of components by Additive Manufacturing in a cost-effective manner,” explained Dr Jörg Henne, Senior Vice President, Engineering and Technology. MTU uses Selective Laser Melting in the production of its borescope bosses for the PurePower®PW1100G-JM geared turbofan engine, which has powered Airbus’s A320neo jetliner since 2013.

The PurePower®PW1100G-JM geared turbofan engine uses metal AM borescope bosses (Courtesy MTU Aero Engines)

As part of Clean Sky, thought to be the largest technology initiative ever launched in Europe, MTU is currently working on a seal carrier manufactured using AM processes. The inner ring, featuring an integral honeycomb structure, will be installed in the high-pressure compressor and is expected to contribute to improving clearance control, and hence increasing efficiency. Additional components, such as bearing housings, brackets and struts, will follow. The company stated that it also plans to further enhance the process monitoring system and improve the surface finish.

MTU first began developing its Additive Manufacturing capabilities more than ten years ago, “making tools, such as spray nozzles and grinding wheels, as well as parts with a simple geometry for experimental testing,” explained Kraus. Later, castings and milled parts were replaced using AM parts, and work on the turbofan engine’s borescope bosses began to pick up speed. Now, MTU stated that it plans to redesign and produce a number of lightweight components across its product offering.