MSC Software signs MoU with RMIT University for use of Simufact Additive

July 10, 2019

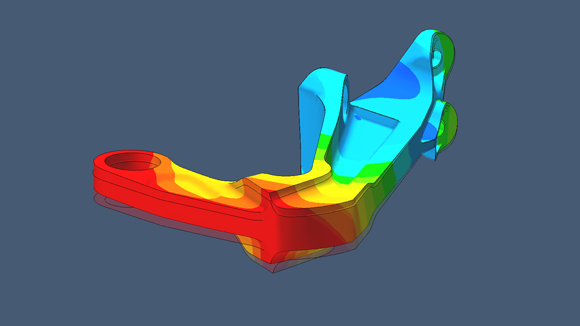

Simulation of an AM part in Simufact Additive, showing bracket distortion after build plate removal (Courtesy MSC Software)

MSC Software Corporation (MSC), headquartered in Newport Beach, California, USA, has signed an agreement with RMIT University, Melbourne, Australia, for the use of Simufact Additive software by the university’s Advanced Manufacturing Precinct. Simufact Additive is a scalable process simulation environment said to enable the first-time-right optimisation of metal Additive Manufacturing processes.

RMIT University is said to house one of the largest Advanced Manufacturing Centres in Australia. Professor Milan Brandt, Technical Director at the Advanced Manufacturing Precinct, RMIT University, stated, “Our vision is to be the leader in the implementation of the next wave of manufacturing in Australia. To this end, we believe in working closely with the best in the industry, both in Australia and internationally; as we go about developing the next generation of engineers, designers and technicians for the world.”

“MSC Software’s Simufact Additive is a great package because it combines the best approaches in one unique software solution through a multi-scaling approach,” he continued. “We find it extremely valuable as it lays the foundation for a wide variability and scalability through different levels of detail for the simulation results.”

Sridhar Dharmarajan, Managing Director for the Indo-Pacific Region, MSC Software, commented, “RMIT’s Advanced Manufacturing Precinct is leading the way in shaping the future of Additive Manufacturing locally with breakthrough research. Therefore, it gives us great pleasure to note that some of the best Additive Manufacturing minds of the future will have an opportunity to work with and understand MSC Software’s Simufact Additive before they embark on their professional careers.”

Dr Hendrik Schafstall, Simufact CEO, added, “Simufact Additive´s capabilities range from generative design & topology optimisation, to process simulation and post processing. This allows one to generate optimised components that are perfectly adapted to the operating conditions and ensure 3D printers can successfully produce the generated design.”