Metal Additive Manufacturing used for production of large scale downhole tool for Oil & Gas sector

July 8, 2016

Jan Kåre Berdal with the finished tool

The Oil & Gas industry demands the highest quality from critical precision components used in a wide range of harsh and demanding applications. The use of metal Additive Manufacturing for component production has, until recently, met with understandable caution. As reported by John Christensen in Maskinregisteret, Norway’s EnergyX is now using metal AM to produce a nozzle component designed for downhole cleanouts of oil and gas wellbores, becoming the first company in this sector to use the technology for the complete production of a large scale downhole tool.

Known to many as the former Bakke Oil Tools, EnergyX has a long history in the Oil & Gas industry. The company is currently in the process of merging with Teco Maskinering, an advanced machining business, with the aim of creating a development and production facility in Ålgård just outside Stavanger, Norway.

“Merging with Teco Maskinering makes it possible for us to create every single component used for our downhole portfolio in-house. In addition to be part of the initial concept stage we follow our customer’s projects all the way from the drawing board to the work site,” stated Jan Kåre Bredal, Project Manager at EnergyX.

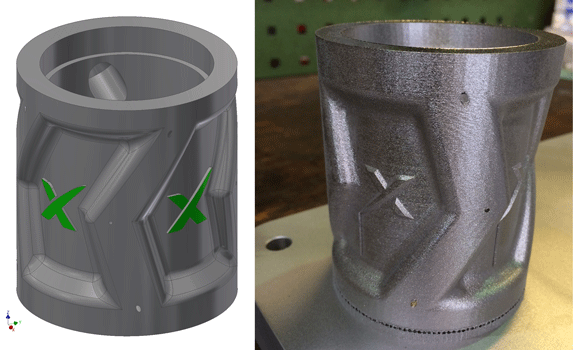

CAD model of the nozzle (left) and the as printed part prior to being cut from its build plate (right)

Working together with Promet AS, EnergyX witnessed the potential of using Additive Manufacturing technology. “While producing a downhole tool for BP Norway we were faced with the challenge of either using Electric Discharge Machining (EDM) to wire cut the primary components or build the same component from smaller sub-components. We then thought, ‘why not 3D Print the components?’ Together with Promet AS we started to optimise the design for the Additive Manufacturing process. Multiple test prints where performed using plastics and then at a later stage in Inconel 718. At this stage we have supplied our customer with a fully qualified product,” Bredal stated.

The finished tool

EnergyX is confident that the Oil & Gas industry will embrace and rapidly adopt the technology. “There are so many upsides to Additive Manufacturing, we are sure to use this method of manufacturing again. The biggest challenge is to learn how to effectively design and manufacture products with this method,” Bredal adds.

Discussing the metal Additive Manufacturing industry in Norway, Eivind Strømland, Marketing Manager at Promet AS, stated, “There are still a lot of developments required and the industry needs to raise the bar when it comes to knowledge and competency about the technology. This specific project was an early adopter of the technology in Norway. But, if we look on a global scale, the train has already left the station. This won’t stop us from getting back in the game but we have to be focused to market all successful projects to raise awareness of metal 3D printing.”